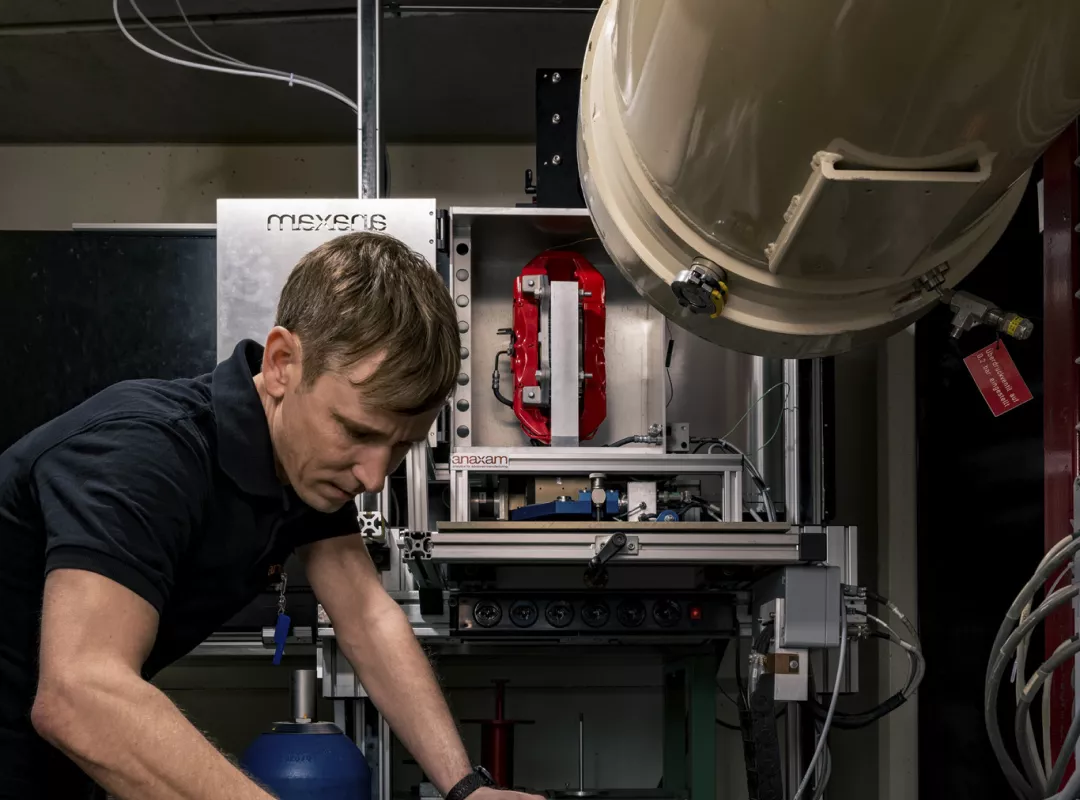

Synchrotron CT for defects analysis of coatings

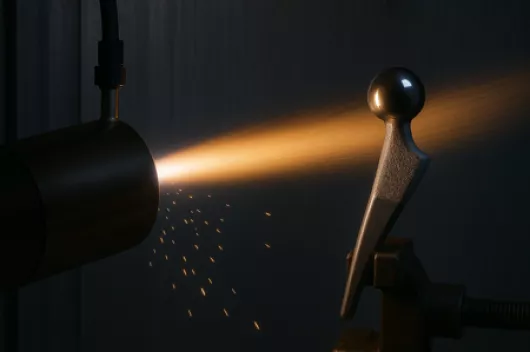

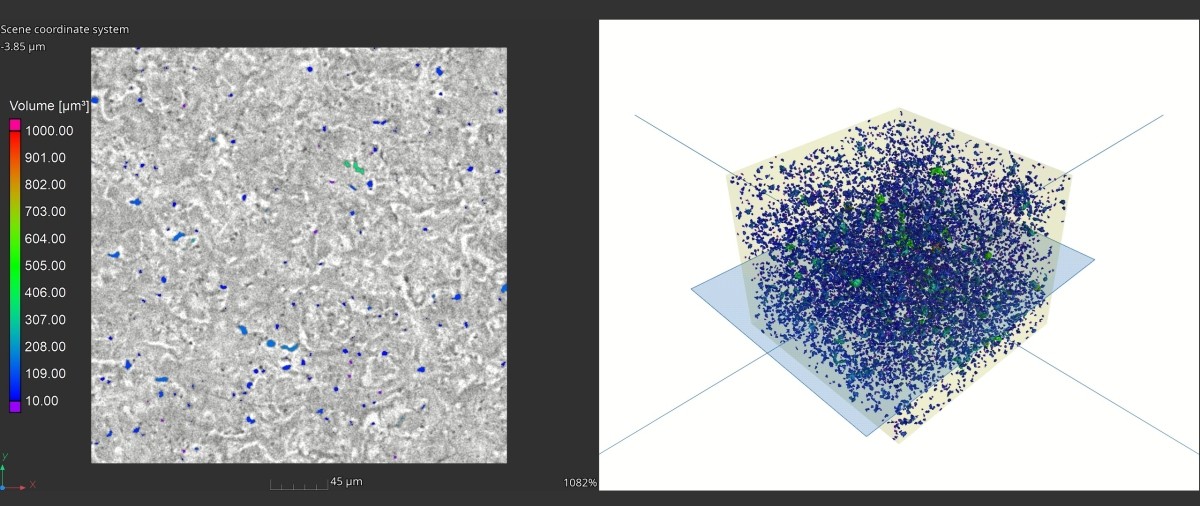

Our advanced imaging expertise allows us to identify even the smallest defects, such as pores in coatings. By leveraging high-resolution synchrotron CT, we obtain detailed insights into the shape, size distribution, and spatial orientation of these defects. This state-of-the-art method delivers an exact three-dimensional representation, enabling precise localization and thorough analysis of potential weak points.

Porosity Analysis

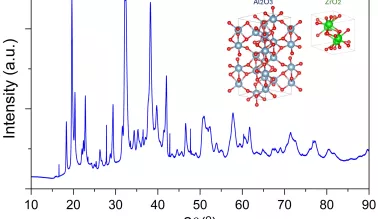

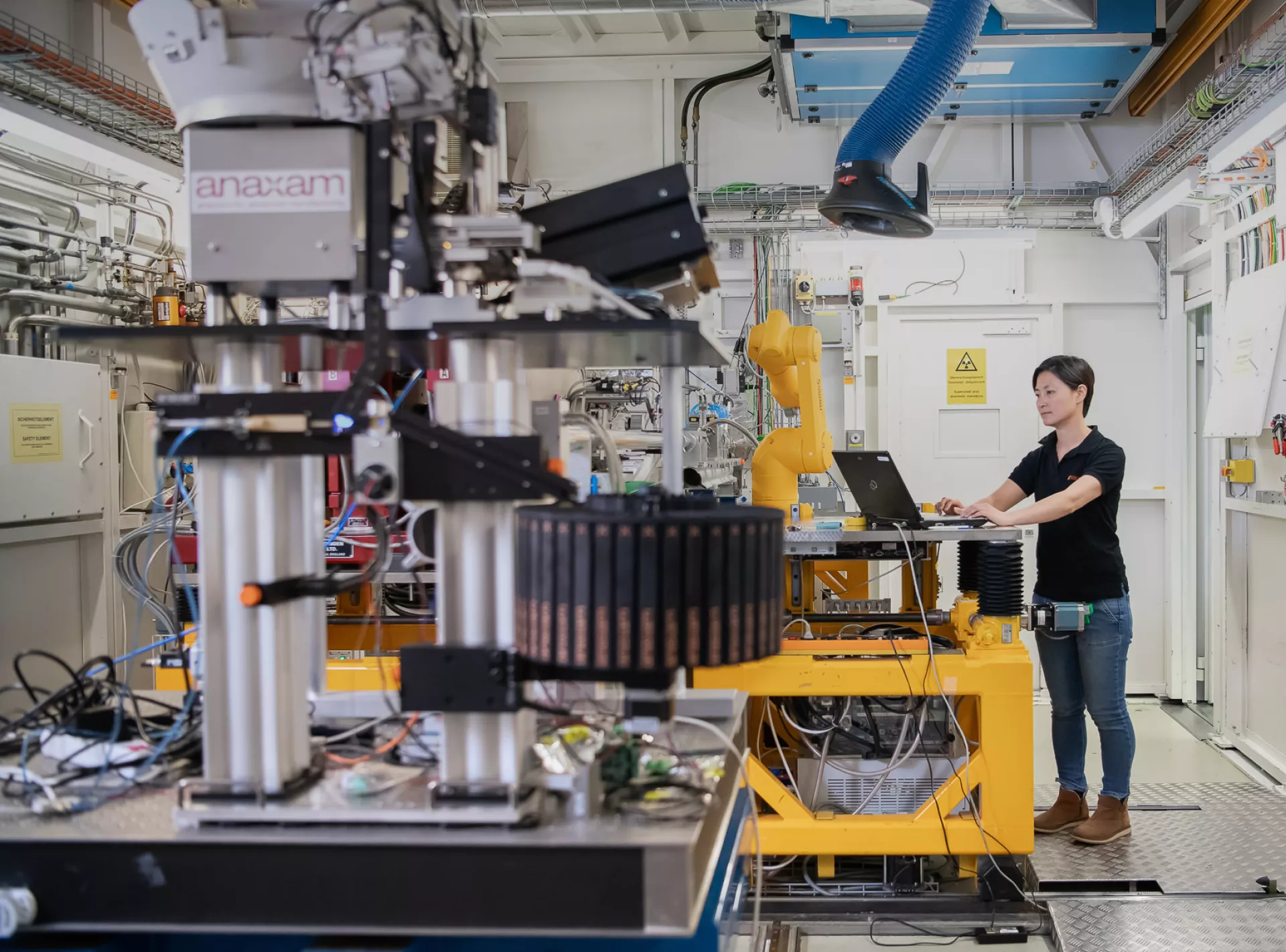

Synchrotron X-ray Diffraction for phase characterization in the coatings

Our expertise in synchrotron X-ray diffraction enables us to characterize phases in thin coating layers with high precision. We can also analyze preferred orientations, grain size, macrostrain, and interface quality. This method provides exceptional depth and sensitivity, making it ideal for studying complex structures and buried interfaces in coatings.

Phase Characterization

These customers trust our expertise

Success stories

Gulhfi highly values ANAXAM’s synchrotron analyses, which provide unique insight into the phase composition of our advanced oxide coatings. These results deepen our understanding of structure–property relationships and support the targeted optimization of our plasma-sprayed coatings. Moreover, they are essential for ensuring precise quality control in the future production of high solar-absorbance coatings.”

Gulhfi AG

The analytical competences of ANAXAM offer a unique possibility compared to lab-based X-ray investigations, in order to develop a robust ceramic surface for the new generation of ternary ceramic oxide coatings.”

Dr. Armando Salito, Director,

Gulhfi AGThe analytical service of ANAXAM offer a unique possibility compared to lab-based X-ray investigations, in order to develop a robust ceramic surface for titanium implants that protects them against wear.“

Roger Burger, General Manager,

Orchid Orthopedics Switzerland GmbHLet’s discuss your challenge

Answers to the most frequently asked questions

Our synchrotron methods are applicable to a wide range of coatings, particularly where in-depth structural, chemical, or stress analysis is critical. These methods are powerful due to their high spatial resolution, non-destructive nature, and sensitivity to elemental and phase information.

Defects in coatings can be visualized using synchrotron CT or laminography, offering complementary insights on the defects of the coating material, such as cracks, pores, delamination, inclusions or layer thickness variations.

Phases in coatings can be analysed with high precision using synchrotron-XRD techniques, thanks to the superior brilliance, collimation, and tunability of synchrotron radiation. Different phases—whether crystalline, amorphous, or mixed—can be characterized in terms of their structure, distribution, and even their evolution under different conditions.

Synchrotron laminography is a powerful imaging technique particularly well-suited for the non-destructive 3D examination of flat, laterally extended samples, such as thin films and coatings on large substrates. Unlike conventional tomography, which rotates the sample around an axis perpendicular to the X-ray beam, laminography rotates the sample around an inclined axis, allowing optimal imaging of planar structures.

Synchrotron techniques are particularly suitable for the investigation of coatings because they offer a combination of high spatial resolution, elemental sensitivity, structural insight, and non-destructive probing that is unmatched by conventional laboratory methods. Coatings often involve thin layers, complex microstructures, or chemical gradients, all of which benefit from the advanced capabilities of synchrotron radiation.

Learn more about us

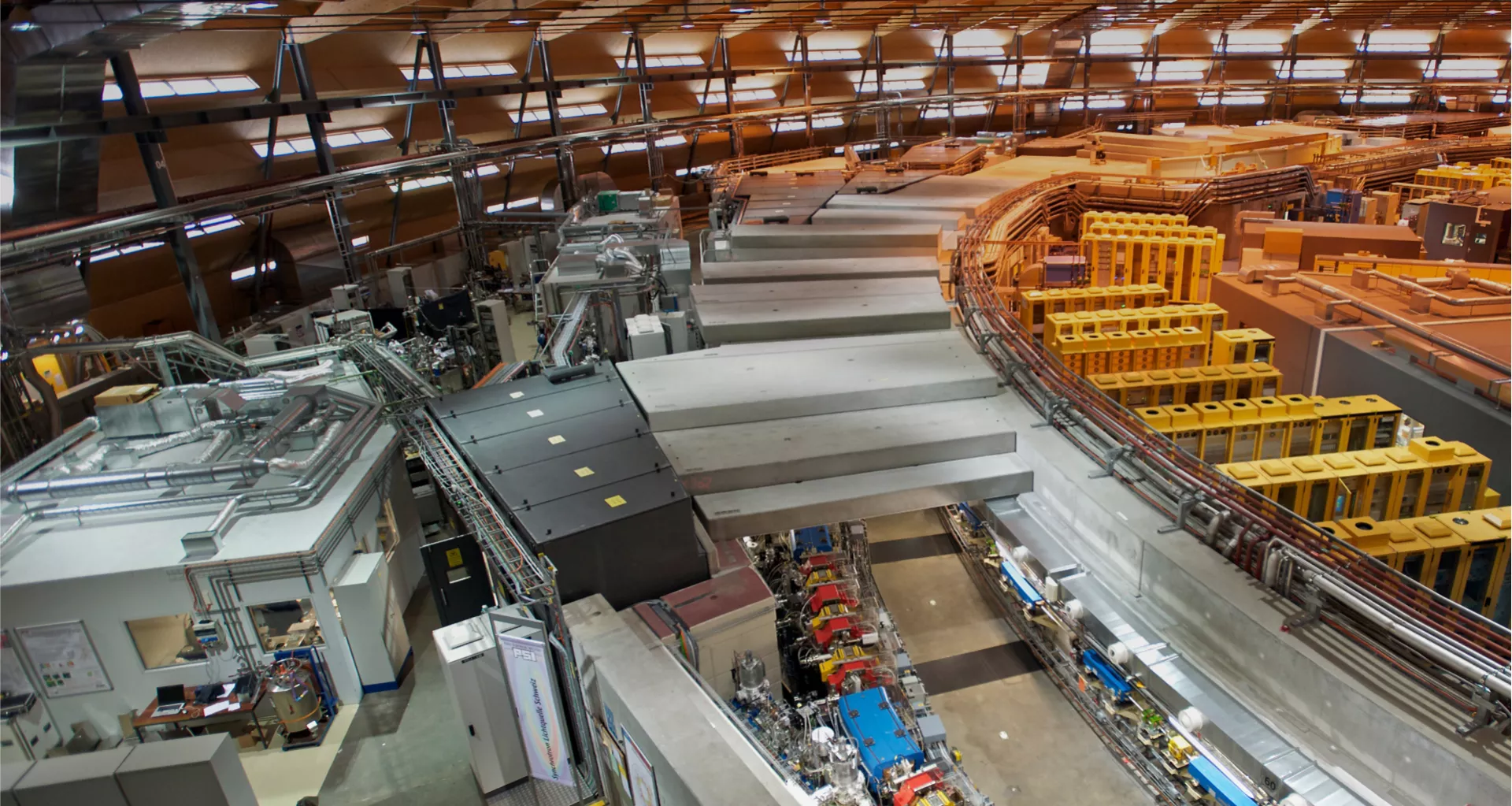

The large-scale research facilities for our applied material analytics with neutron and synchrotron radiation

Tap the pins to explore

The way we work with you

Your

challenge

Competent

consulting

Applied material analytics with Neutron and Synchrotron radiation &

tailor-made infrastructure

Data analysis and interpretation

Final

report