Investigation of Phases and Optical Properties of Plasma-Sprayed Alumina–Titania Coatings Using Synchrotron Grazing Incidence Diffraction

Gulhfi AG is an international innovation leader in the field of surface engineering and surface functionalization. Their core business is developing and delivering (i) a new generation of plasma torches able to produce engineered coatings, and (ii) surface engineering finishing services, and related technologies—especially for industries such as medical, aerospace, energy, automotive, and general manufacturing. One of their key technical offerings is the DEBYE-LARMOR cascade plasma torch technology, which allows precise control over plasma spraying parameters and is optimized to produce coatings with high roughness or porosity when needed. They also provide services in coating development, prototyping, powder/material development, robotic programming of spray processes, and implementation of coating production lines for customers.

Gulhfi develops advanced oxide coatings for concentrated solar power (CSP) absorbers to address the critical challenge of combining high solar efficiency with long-term durability under demanding thermal conditions. In CSP systems, absorber surfaces must operate at elevated temperatures while maintaining strong solar absorptance and low thermal emittance to maximize performance. Conventional oxides such as alumina and titania offer excellent stability, wear resistance, and corrosion protection, but in their natural state they are optically unsuitable due to their low absorptance. By leveraging its proprietary plasma-spraying technology, Gulhfi transforms these oxides into dark, complex ceramic coatings with optimized optical properties.

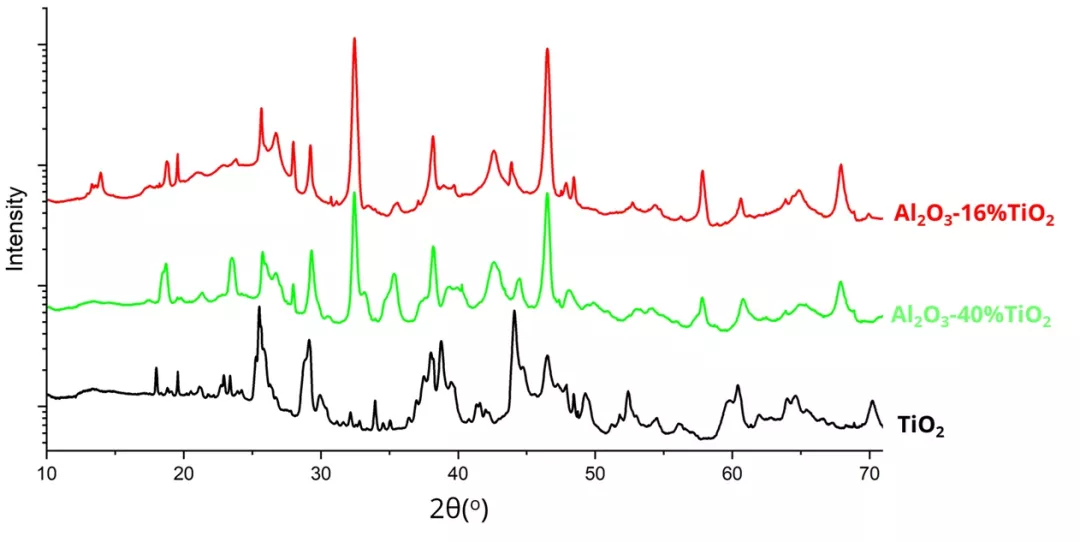

The applied material analytics of ANAXAM using Synchrotron Grazing Incidence X-Ray Diffraction, enables a detailed understanding of the phase composition within the coatings after the plasma spraying process. By correlating the identified phases with the measured solar absorptance, this approach provides crucial insights into the structure–property relationships that govern coating performance. Such knowledge not only explains the origin of optical behavior but also guides the optimization of spraying parameters, allowing the properties of the coatings to be finely tuned and further enhanced for high-efficiency solar applications.

Gulhfi greatly values ANAXAM’s Synchrotron analyses which provided unparalleled insight into the phase composition of our advanced oxide coatings. These results deepen our understanding of the structure–property relationships and in guiding the optimization of our plasma-sprayed coatings. Additionally, such high-resolution results are essential to guarantee a precise quality control in the future production of high solar absorbance coatings.”

Dr. Armando Salito, Director

Gulhfi AG