analyze more precisely

Material analytic using neutron and synchrotron radiation

for the products and processes of tomorrow.

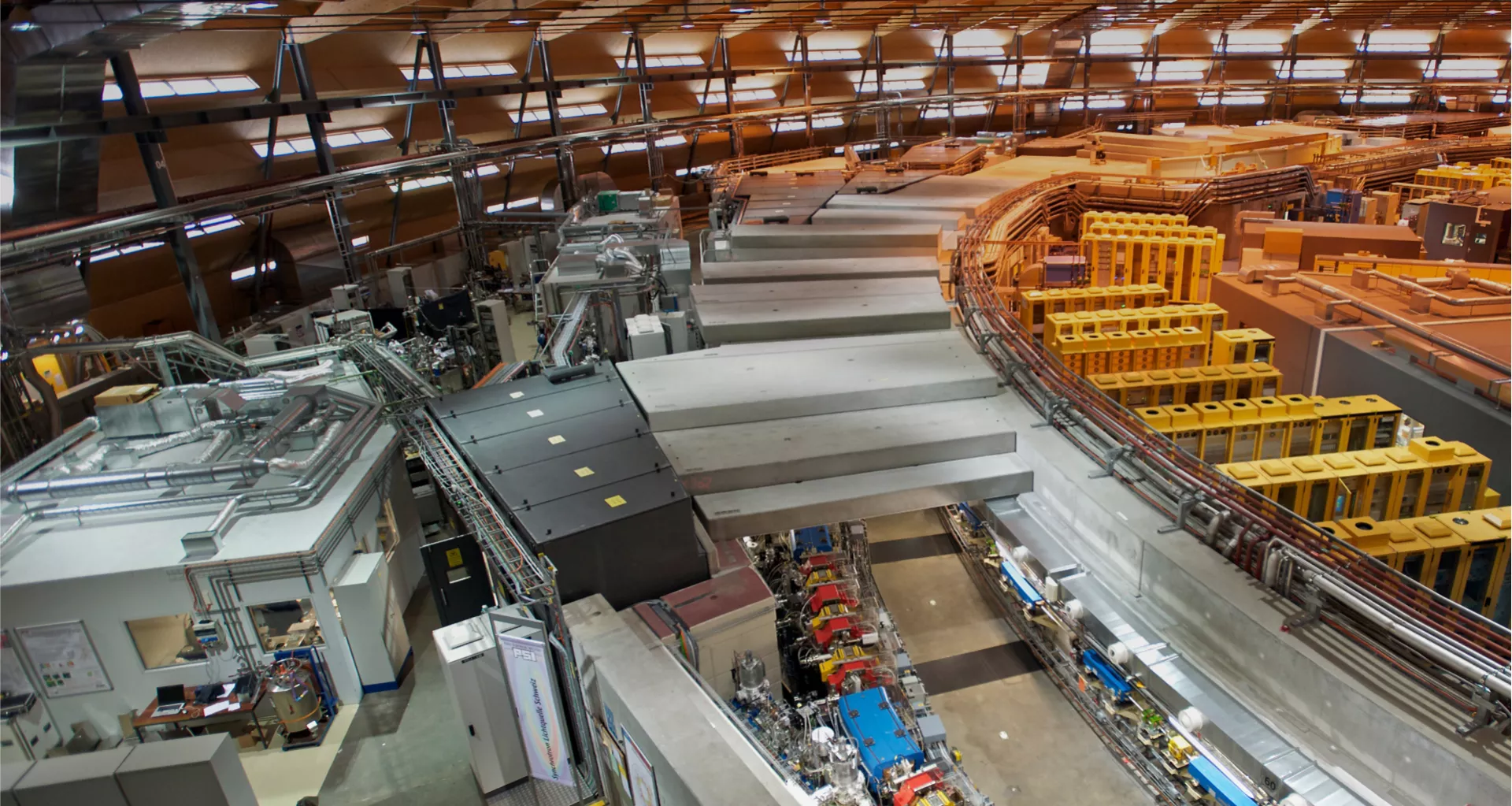

Large-scale research facilities enable deeper insights

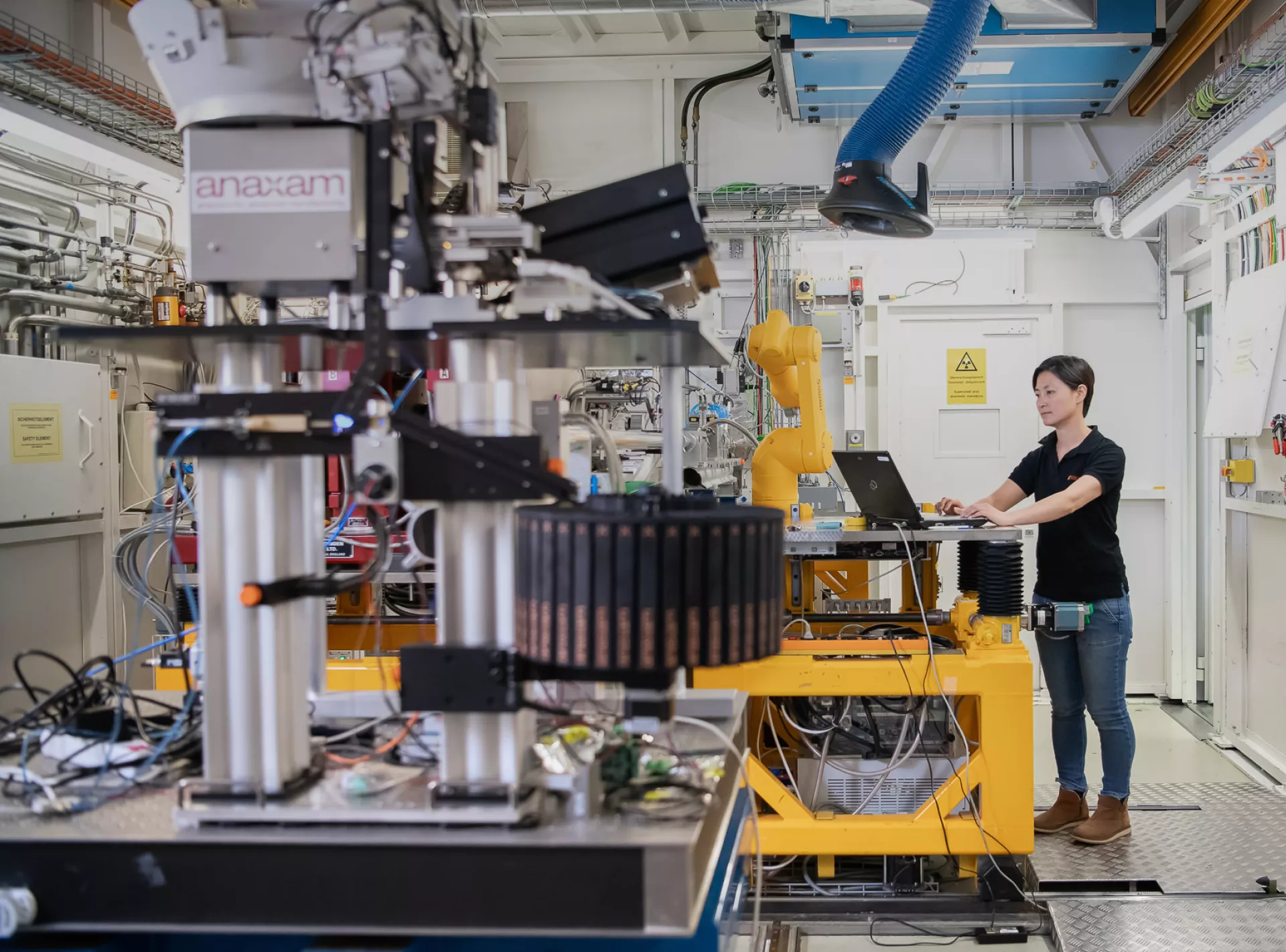

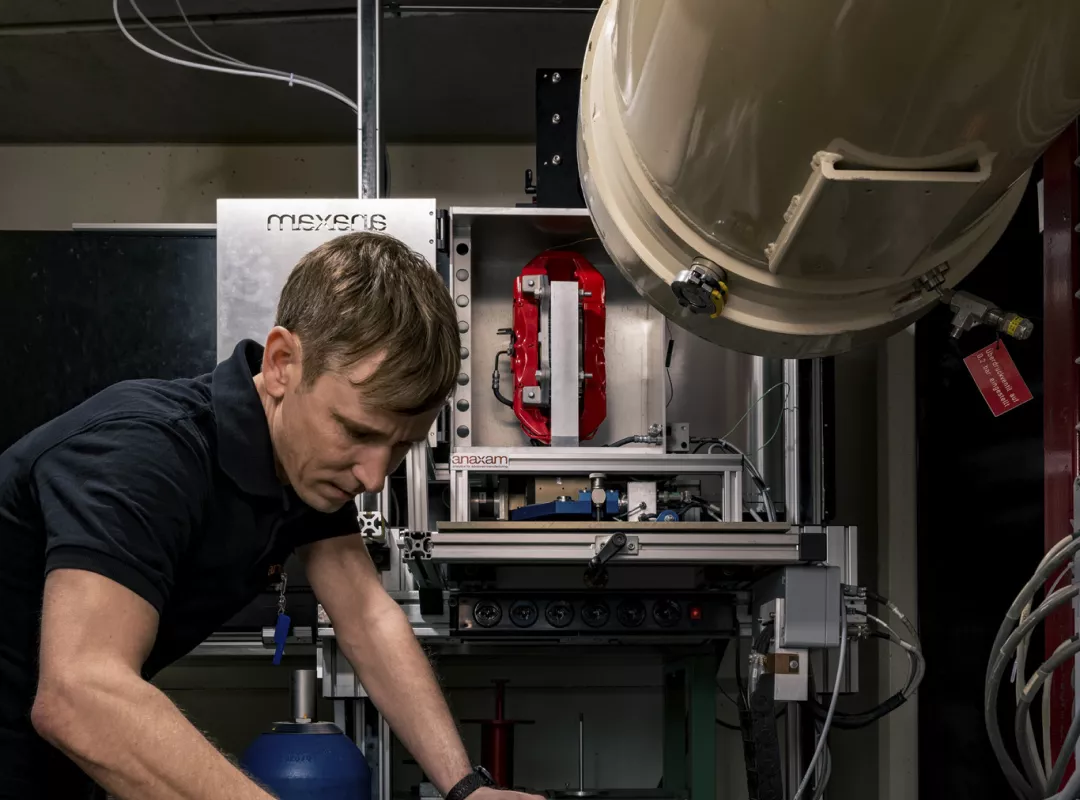

We provide industry with access to advanced methods of material analytics based on neutron and synchrotron radiation (X-rays), primarily at the Paul Scherrer Institute (PSI). Originally developed for fundamental research, these methods now offer unique insights into materials and processes.

Tap the pins to explore

We break the boundaries of material analytics

With us, you gain access to analytics at large-scale research facilities to address your industrial and application-driven challenges. This opens up entirely new dimensions in material analytics, allowing you to look deeper into materials — non-destructively and in greater detail than ever before.

Material analysis that pushes boundaries:

In terms of:

- Spatial resolution

- Real-time investigations

- Contrast modality

- Sample throughput

A selection of our clients

Client logos are shown with prior approval.

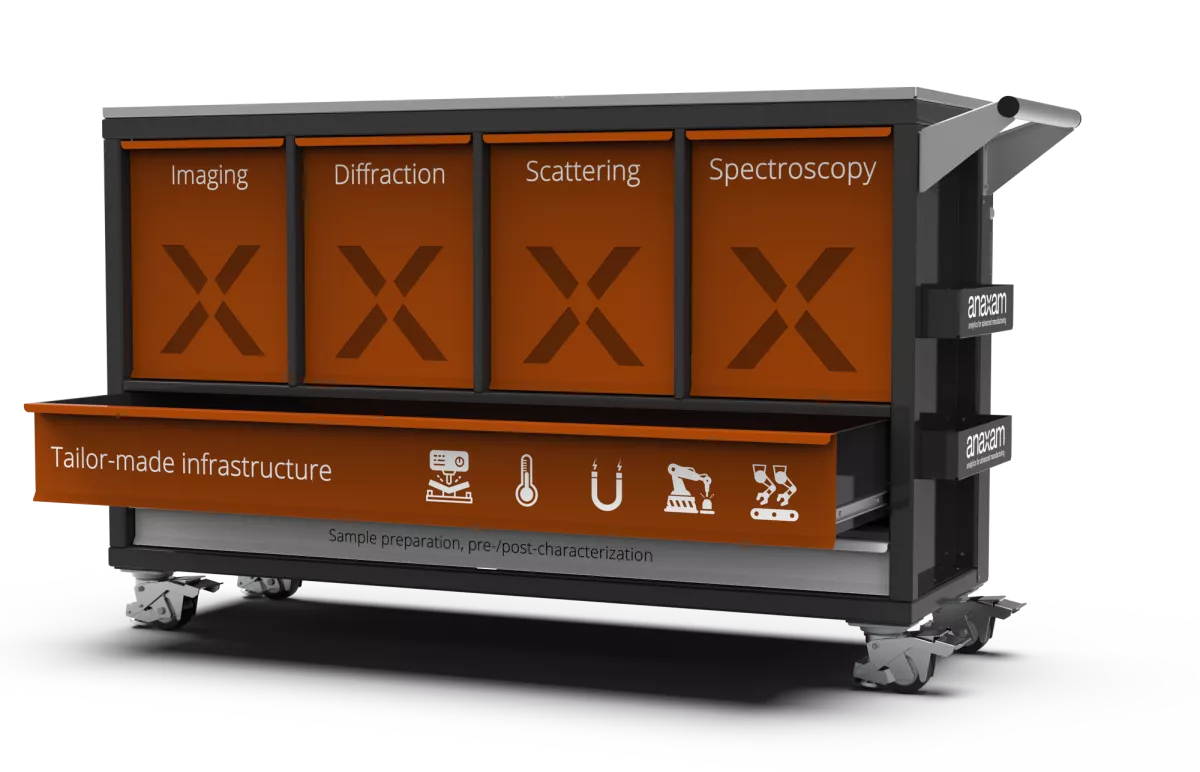

Our specialized tools for your specific challenges

This is how we analyze your challenges – making the invisible visible: precise, reliable, and reproducible.

Open the drawers and learn more:

Sample preparation and pre- /post- characterization

Move your mouse over the drawers to explore our tools for applied material analytics.

Click the drawers to learn more

Tap the drawers to learn more

Together, we’ll find the right solution

Let’s discuss how we can support you with your specific challenge – the best way to find out is through a personal conversation.

How we work with you

When it comes to industrial challenges, you can rely on our careful, practice-oriented and solution-focused approach.

Your

challenge

Competent

consulting

Applied material analytics with Neutron and Synchrotron radiation &

tailor-made infrastructure

Data analysis and interpretation

Final

report

We’re here to help

Industrial challenges can be highly specific. We’d be happy to discuss your individual case in detail. Schedule a meeting with us to learn how we can contribute to finding the right solution.

Stay up to date with us

Our newsletter keeps you informed about:

- Upcoming online seminars, workshops, and training events

- Insights from ANAXAM – our newsletter is sent only 4 times a year

- Availability in both English and German – switch the language to receive our News in English

- You can pause or unsubscribe from the newsletter at any time.

- We take data protection very seriously (DSG compliant). You can read our privacy policy here. By subscribing, you agree that we may store and process your details to contact you and keep you informed. You can withdraw your consent at any time.