Diffraction

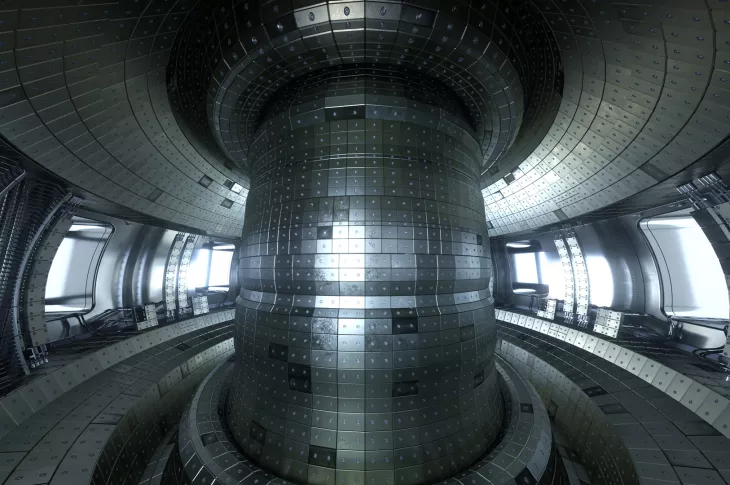

Neutron and Synchrotron Diffraction – Two complementary methods for providing structural information

Your benefits compared to lab-based analytics

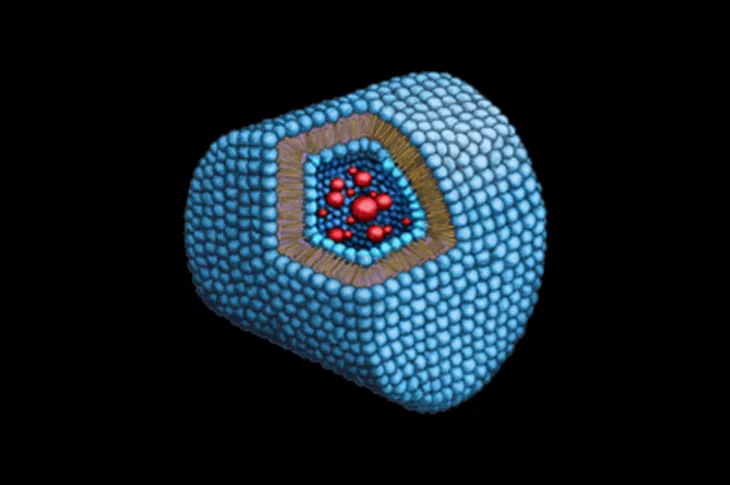

The materials that make up an industrial product often go through complicated processes before they reach their final shape and form. Every process that has been performed influences the final structure, and therefore the properties, of the product. Diffraction and Small-Angle Scattering are methods available for detecting phases and their morphologies.

Synchrotron techniques provide high transmission with light elements, and strong contrast with heavier elements. Neutron techniques, on the other hand, provide strong contrast with light elements, and higher transmission with heavier elements. This means that the four methods offer different yet complementary contrast possibilities.

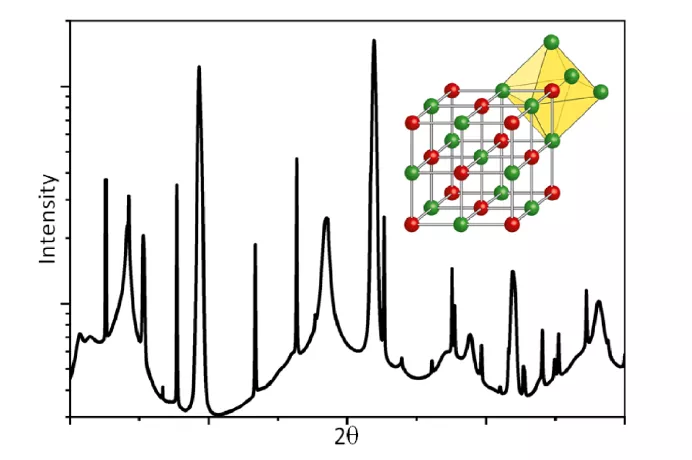

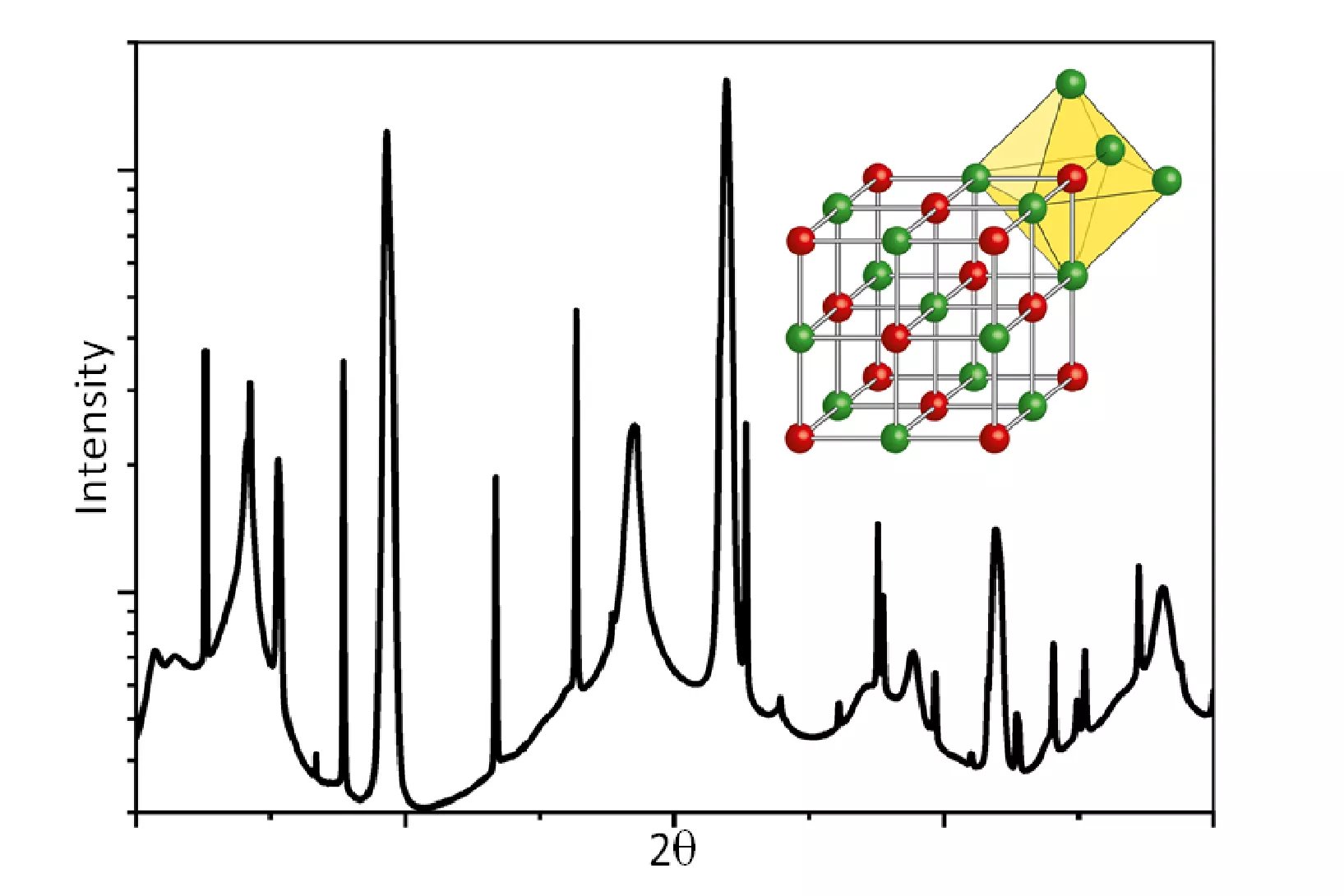

Diffraction can be used for structural characterization, as well as textures and residual-stress analysis.

Neutron and Synchrotron techniques deliver high resolution, high throughput, and allow real-time investigations. The data obtained provides the basis for further analytical capabilities, as described below.

We are looking forward to working with you.

Diffraction is used as a qualitative and quantitative measurement technology with the following analysis capabilities:

Atomic phase and structural characterization

- Identification of different phases, and the volume fraction of different phases

- Characterization of grain size

- Characterization of textures

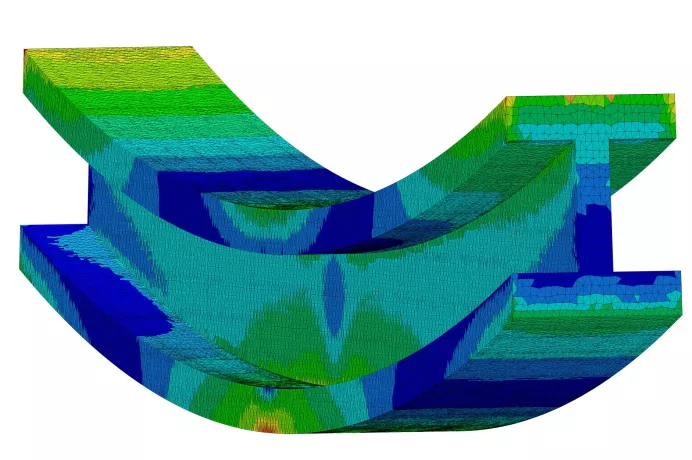

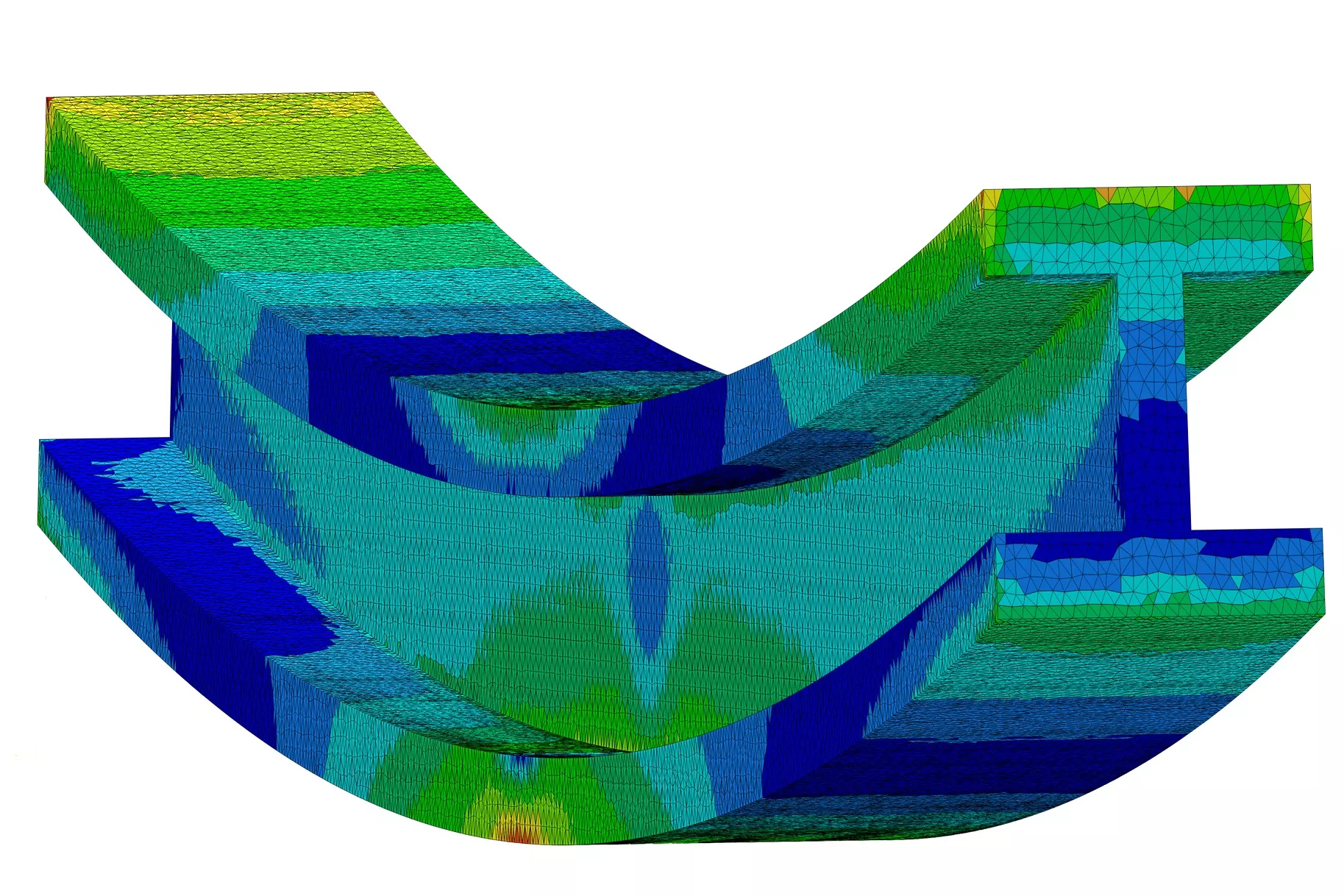

Residual stress analysis

- Quantitative analysis of strain in samples

- Differentiation of regions with different residual stresses

We’re here to help

Industrial challenges can be highly specific. We’d be happy to discuss your individual case in detail. Schedule a meeting with us to learn how we can contribute to finding the right solution.

The complementarity of Neutron and Synchrotron Diffraction

Selection of advantages of each technique

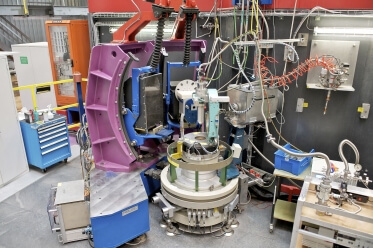

Neutron Diffraction

- Higher sensitivity for light elements (such as H, B, Li)

- Higher penetration of metallic elements (such as Ti, Cr, Fe)

- Higher contrast difference for neighbouring elements (as example Pd and Rh)

- Sensitive to magnetic structures

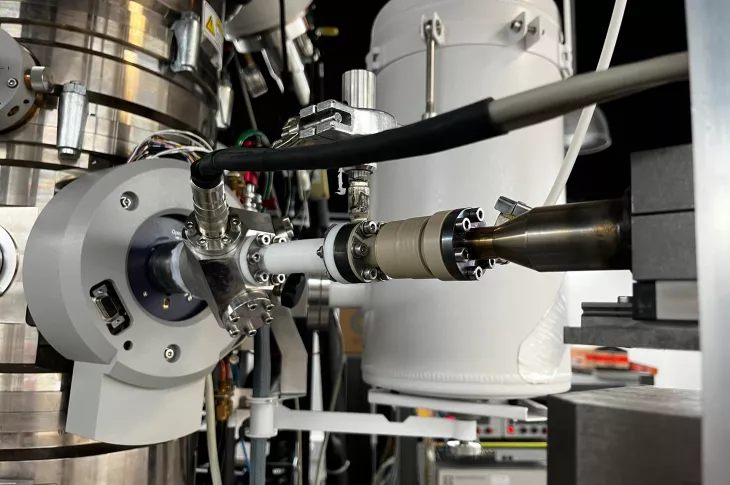

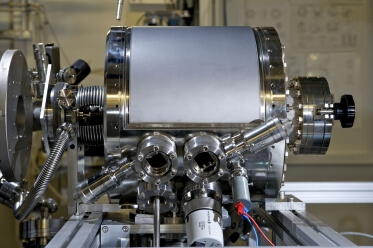

Synchrotron Diffraction

- Higher penetration for light elements (Such as H, B, Li)

- Higher sensitivity for metallic elements (such as Ti Cr, Fe)

- Higher spatial resolution compared to neutrons and lab-based X-ray systems

- Much higher temporal resolution compared to neutrons and lab-based X-ray systems

- Much higher sample throughput compared to neutrons and lab-based X-ray systems

Technical details of Neutron and Synchrotron Diffraction

Selection of detailed information

| Information | Neutron Diffraction | Synchrotron Diffraction |

|---|---|---|

| Spot Size | Up to 1 mm x 5 mm maximum | Down to 40 µm x 130 µm minimum |

| Resolution | 0.05 % | 0.02 % |

| Temporal resolution | Up to 100 Hz | Up to 100 KHz |

| Energy range |

2.3 - 25 meV |

5 - 38 keV |

| Wavelength | 1.8 - 6 Å | 0.3 - 2.5 Å |

|

Flux |

~ 106 cm-2 s-1 |

~ 1013 cm-2 s-1 |

The way we work with you

Your

challenge

Competent

consulting

Applied material analytics with Neutron and Synchrotron radiation &

tailor-made infrastructure

Data analysis and interpretation

Final

report

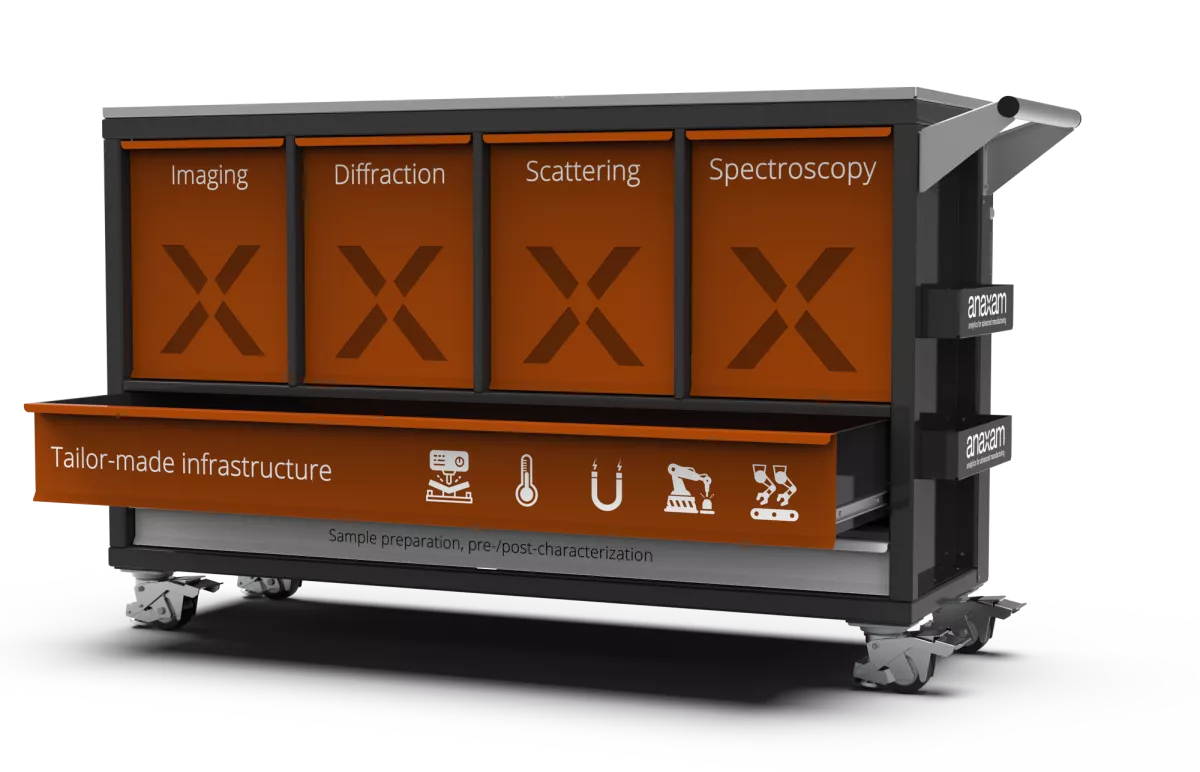

Our specialized tools for your specific challenges

This is how we analyze your challenges – making the invisible visible: precise, reliable, and reproducible.

Open the drawers and learn more:

Sample preparation and pre- /post- characterization

Move your mouse over the drawers to explore our tools for applied material analytics.

Click the drawers to learn more

Tap the drawers to learn more