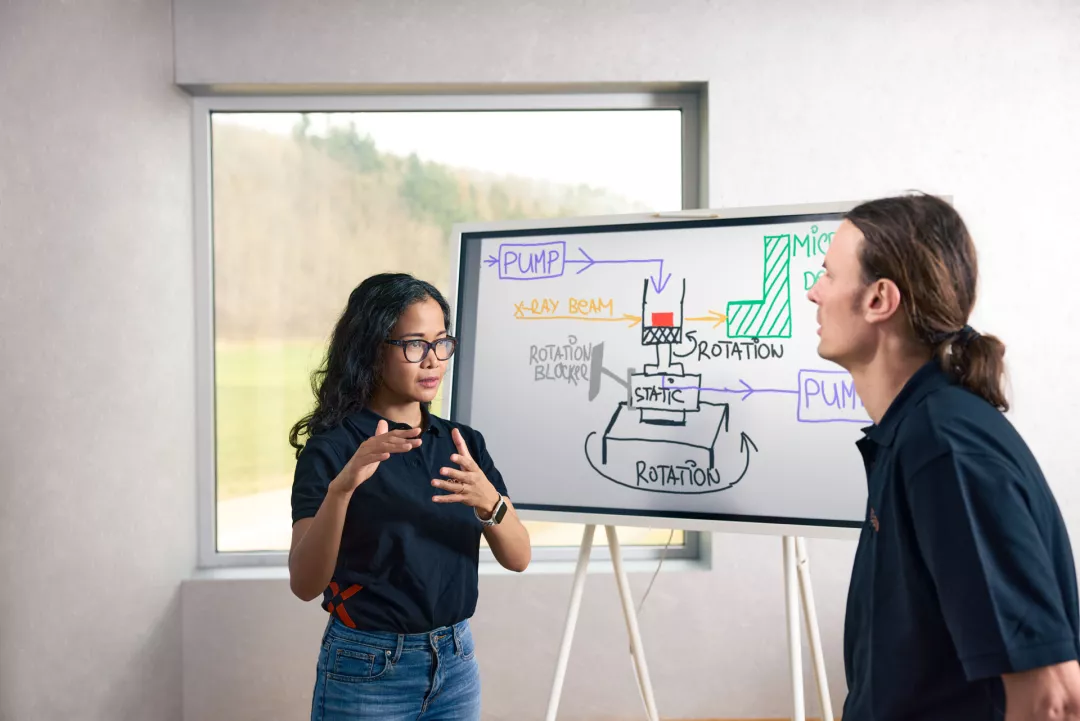

Tailor-made infrastructure for real-time investigation of the dissolution behaviour of tablets using Synchrotron CT

During manufacturing

Volume flow min.

0

nl/min

Volume flow max.

0

ml/min

pH value of the solution

adjustable

Year of manufacture

0

Control

Volume flow

Branche

Medical technology

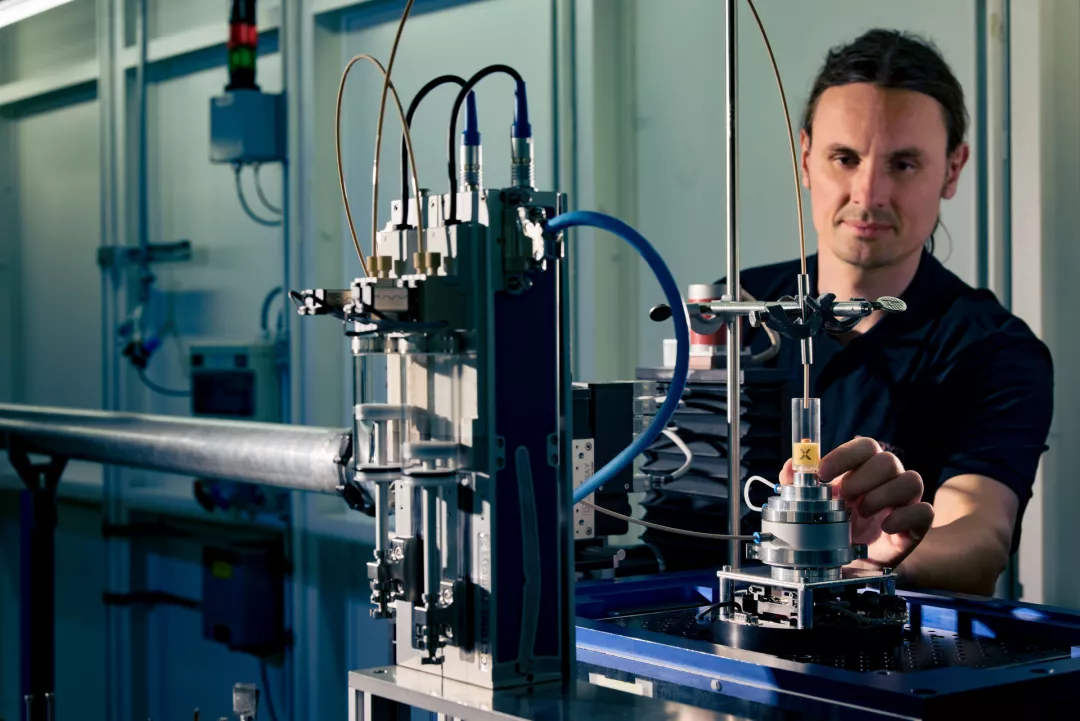

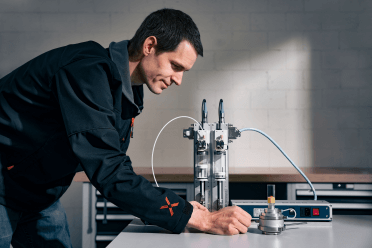

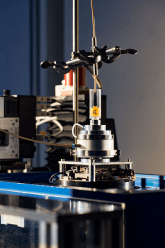

• Measuring cell to fix and rinse the tablet

• Highly precise and adjustable volume flow

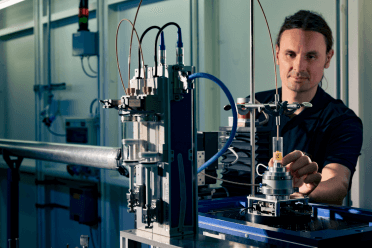

• Possibility for tomography measurements

• Measuring cell with grid bottom for ideal rinsing around the tablet

• High-precision volume flow controlled by syringe pumps

• Rotary liquid feed-through for tomography measurements

• Production of the measuring cell using 3D printing process

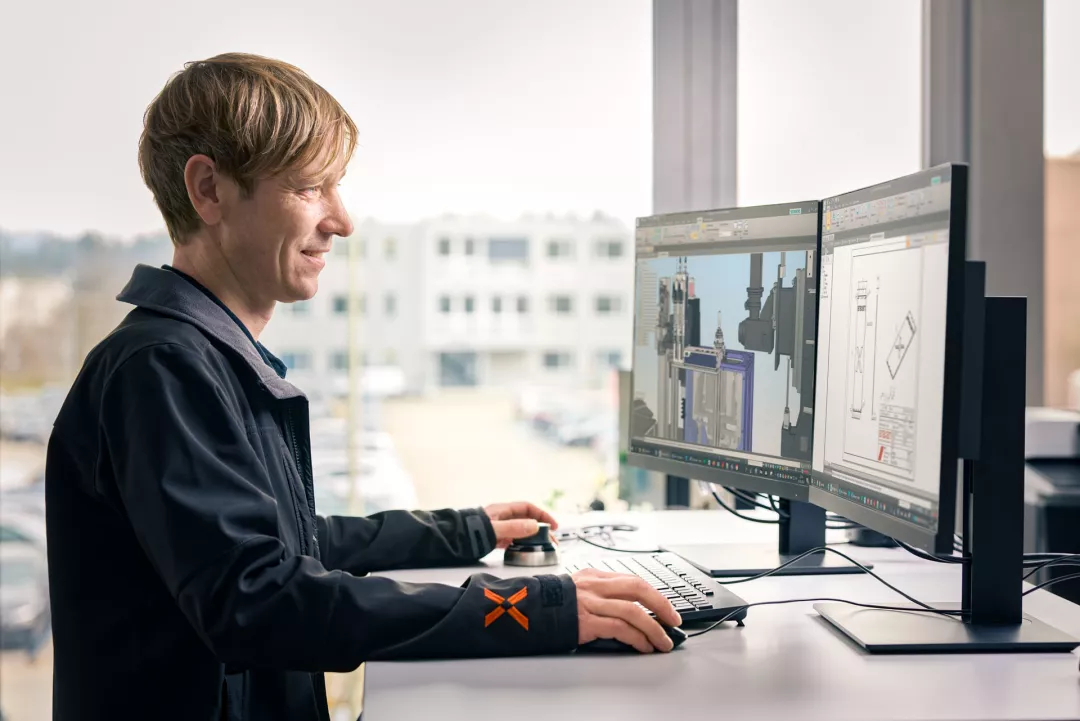

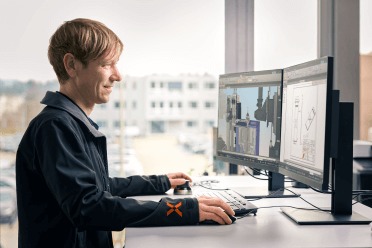

• Installation and commissioning of the hardware and software

• Controller tuning and acceptance tests in the laboratory

• Setting up the tablet dissolution infrastructure at the beam line

• Setting up the software for interface communication

• Carrying out the customer-specific experiments

During manufacturing

Volume flow min.

0

nl/min

Volume flow max.

0

ml/min

pH value of the solution

adjustable

Year of manufacture

0

Control

Volume flow

Branche

Medical technology

Click to copy video link

Copied

Tailor-made infrastructure for real-time investigation of the dissolution behaviour of tablets using synchrotron CT

Any question? Feel free to contact us