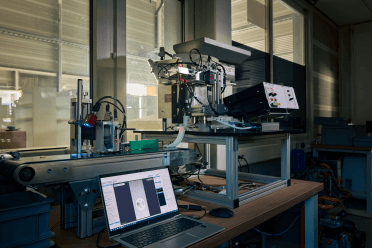

Tailor-made infrastructure for the labelling of sample containers

• Sample handling as bulk goods

• Automatic sample feeding and sample storage > 10,000 pieces

• Automatic container orientation

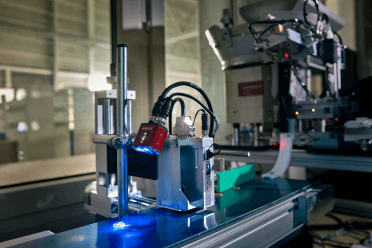

• Printing of the containers with a Data Matrix Code (DMC)

• Printing frequency > 30 containers per minute

• 100% quality control after printing

• Automatic feeding by bowl feeder > 10,000 pieces onto the conveyor belt

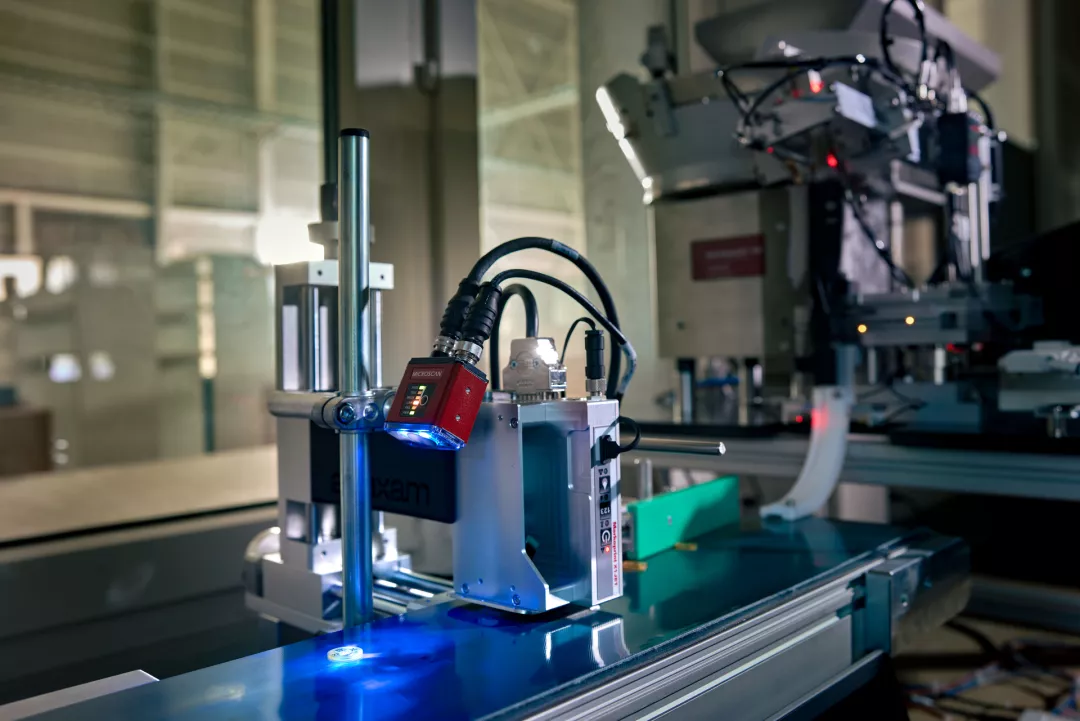

• Container feeding to the printer by using a conveyor belt

• Container labeling by using the inkjet printing method

• 100% quality control by scanning the Data Matrix Code (DMC) after printing

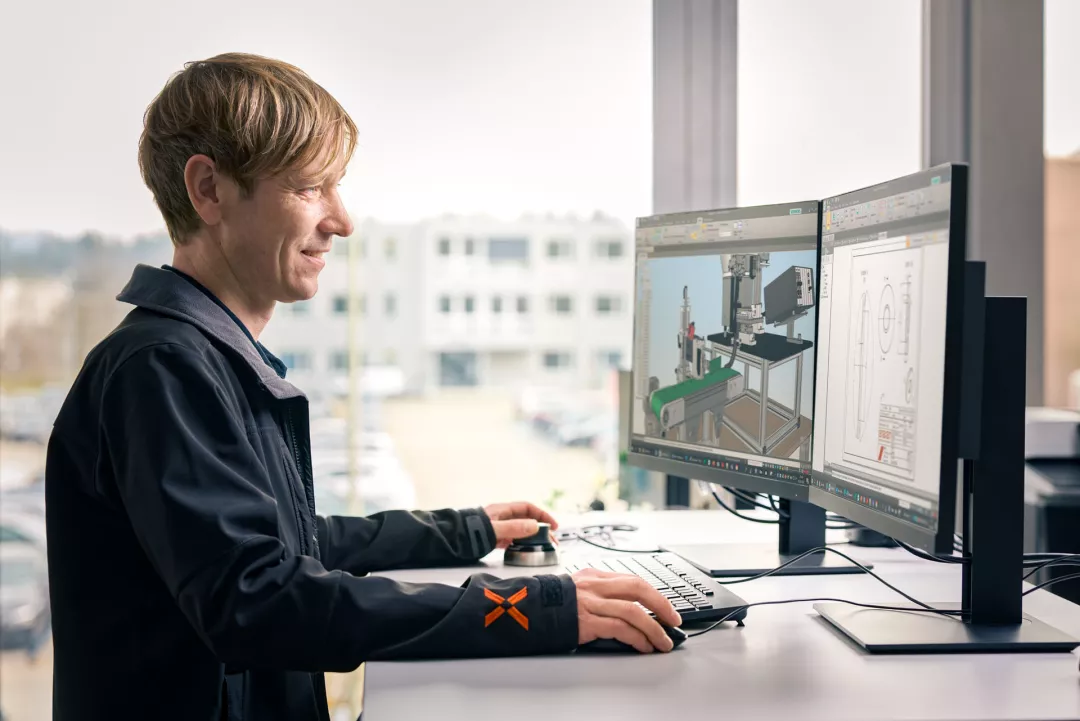

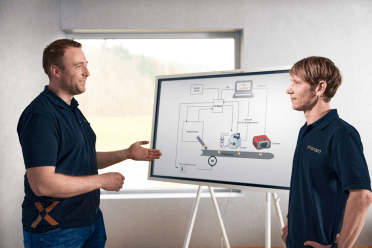

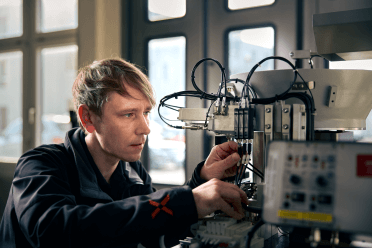

• Software development for the measurement and control system

• Ordering and manufacturing of the individual components

• Installation and commissioning of the hardware and software

• Software tuning and acceptance tests

• Labelling of the customer containers with a Data Matrix Code (DMC) and a number sequence.

• 100% quality control after printing by reading the Data Matrix Code (DMC)