Tailor-made infrastructure for the investigation of micromovements on brake components for Neutron Imaging

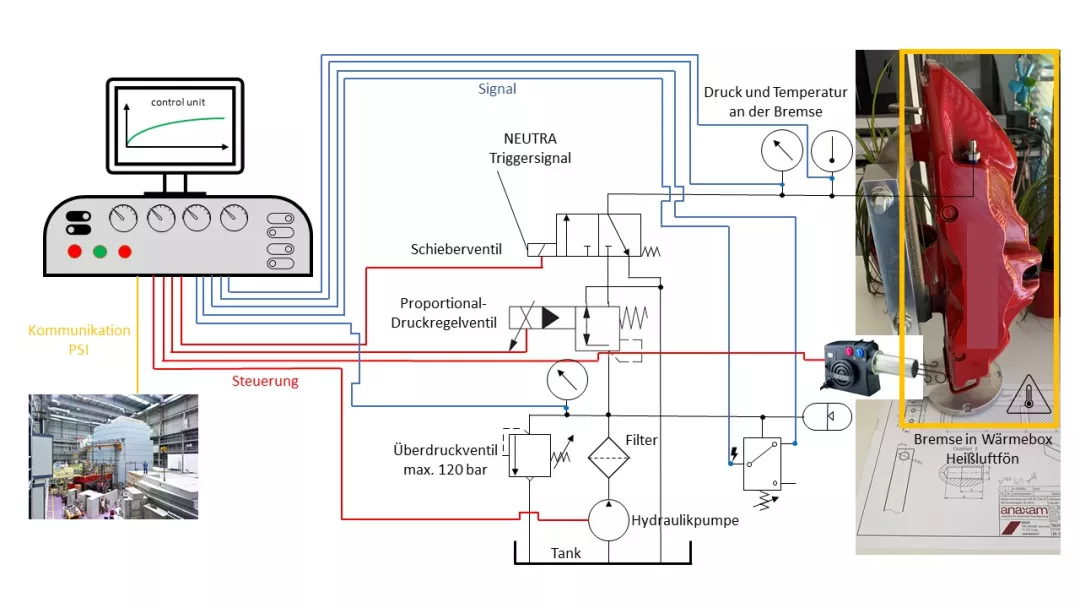

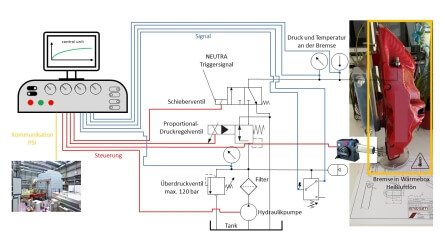

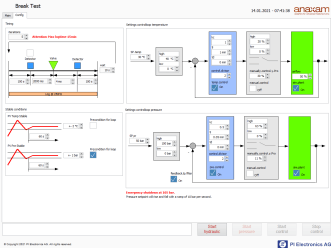

• Pressure measurement directly at the brake caliper

• Pressures up to a maximum of 100 bar

• Pressure control accuracy of 0.5 bar

• Freely programmable pressure curves / pressure cycles

• Temperatures up to a maximum of 100 °C

• Temperature control accuracy of 1.0 °C

• Temperature control on brake fluid temperature

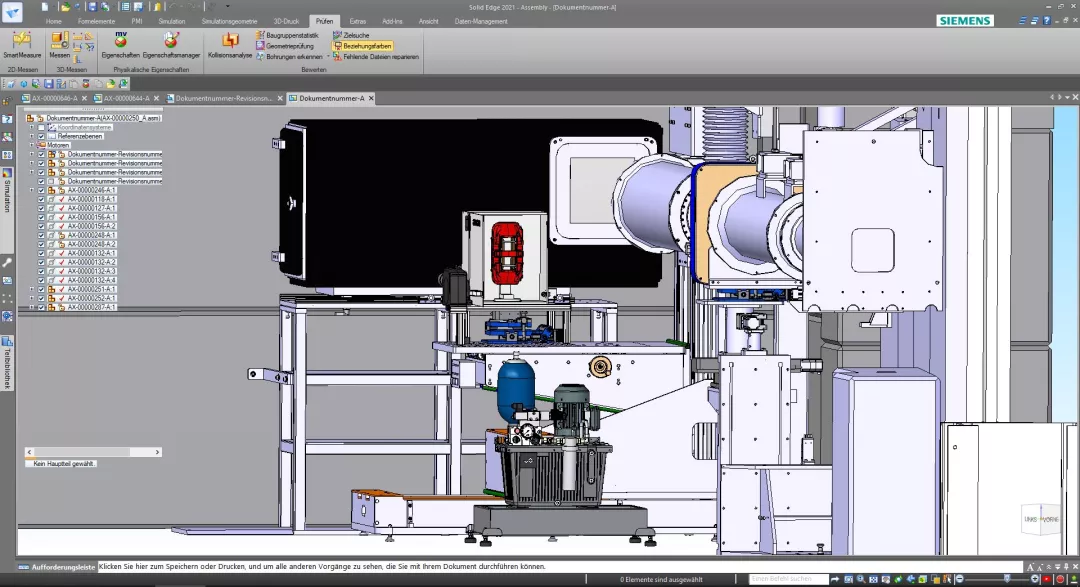

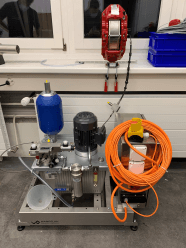

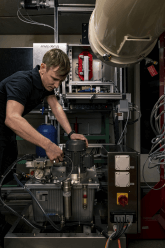

• Hydraulic unit for an optimal pressure control

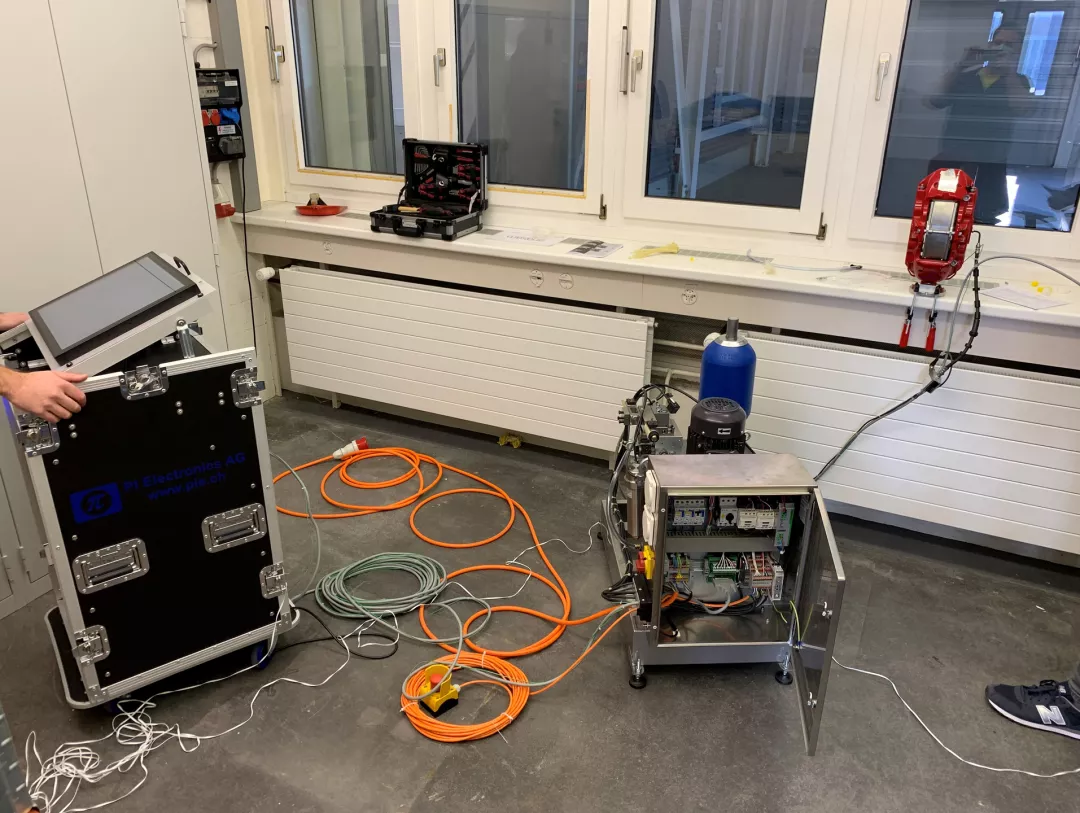

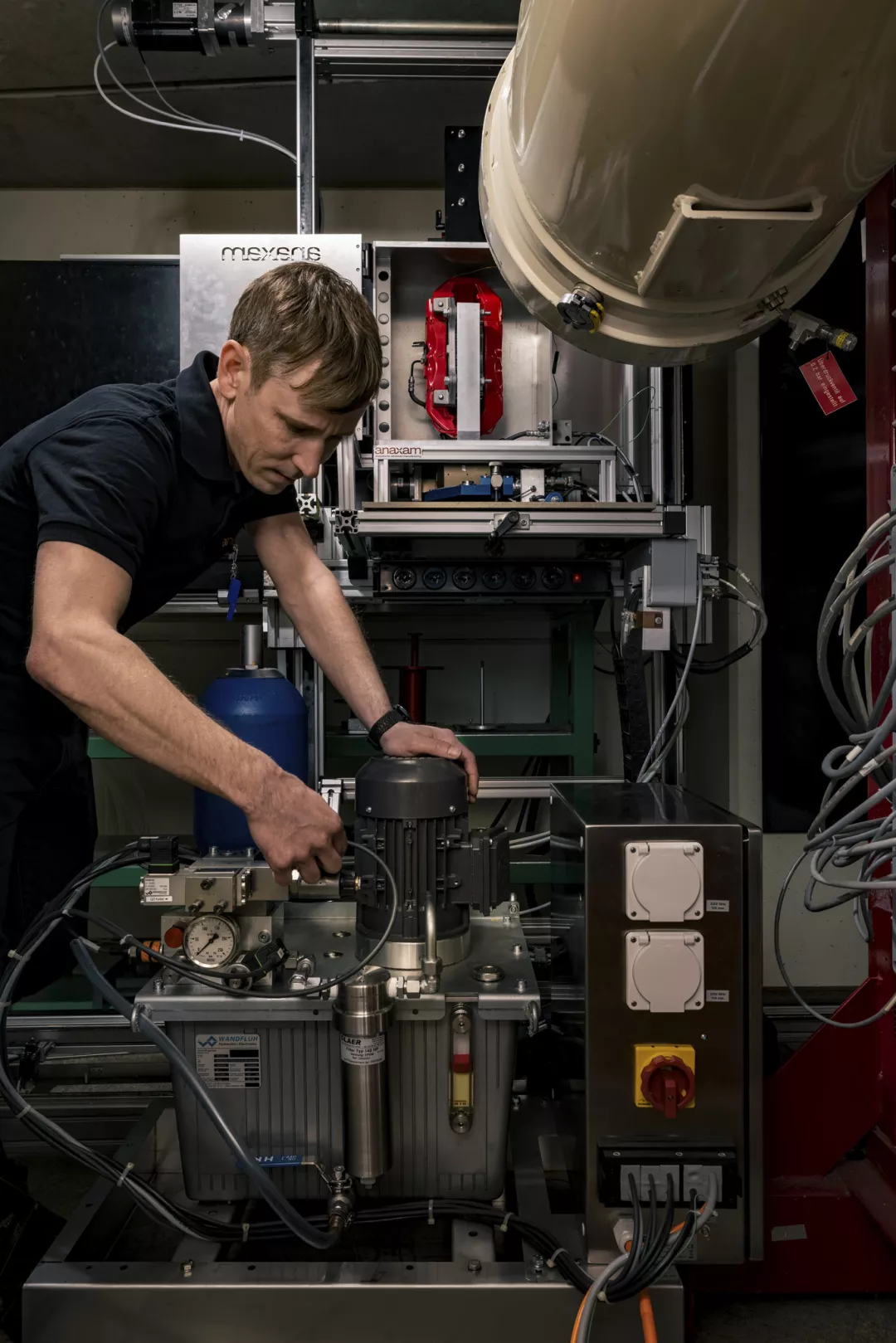

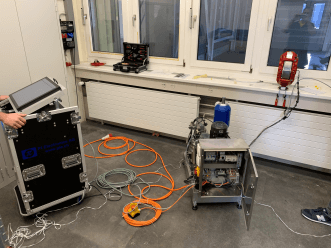

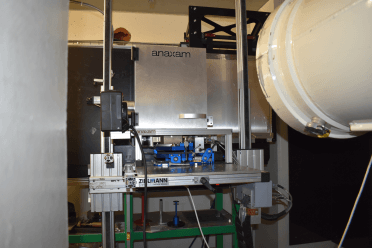

• Hydraulic unit as mobile unit

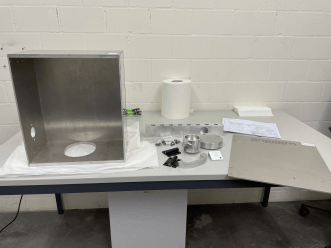

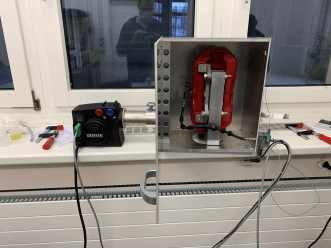

• Climatic chamber for easy caliper change and good temperature control

• Pressure and temperature measurement directly at the brake caliper

• Manufacturing of the climatic chamber and the hydraulic unit

• Assembly and commissioning of the hardware and software

• Controller tuning and acceptance tests in the laboratory

• Set up the climatic chamber and hydraulic unit on the beam line

• Set up software interface communication

• Carrying out the customer-specific experiments