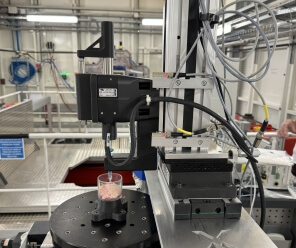

Tailor-made infrastructure for the controlled injection of prefilled syringes (PFS) into tissue samples

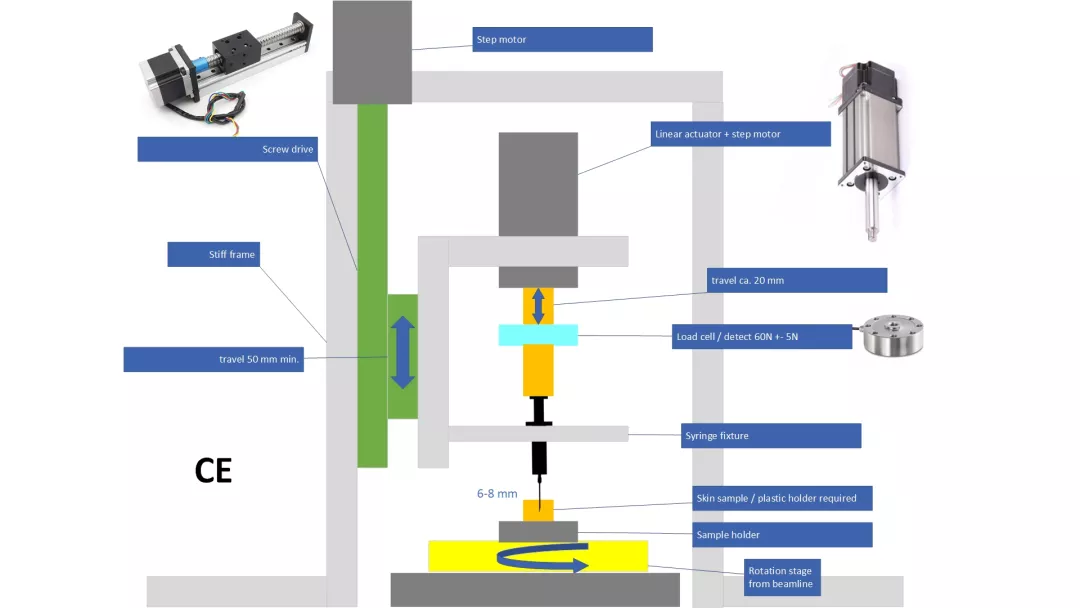

• Easy sample change

• Controlled positioning of the syringe needle

• Controlled injection

• Force-displacement measurement during the injection process

• Force switch-off to protect the syringe

• CE conformity

• Linear unit for positioning the syringe needle with 150 mm travel

• Injection motor with 40 mm travel

• Linear table with micrometer screw for precise positioning of the needle above the sample

• 3D-printed base holder for holding a wide variety of syringe types

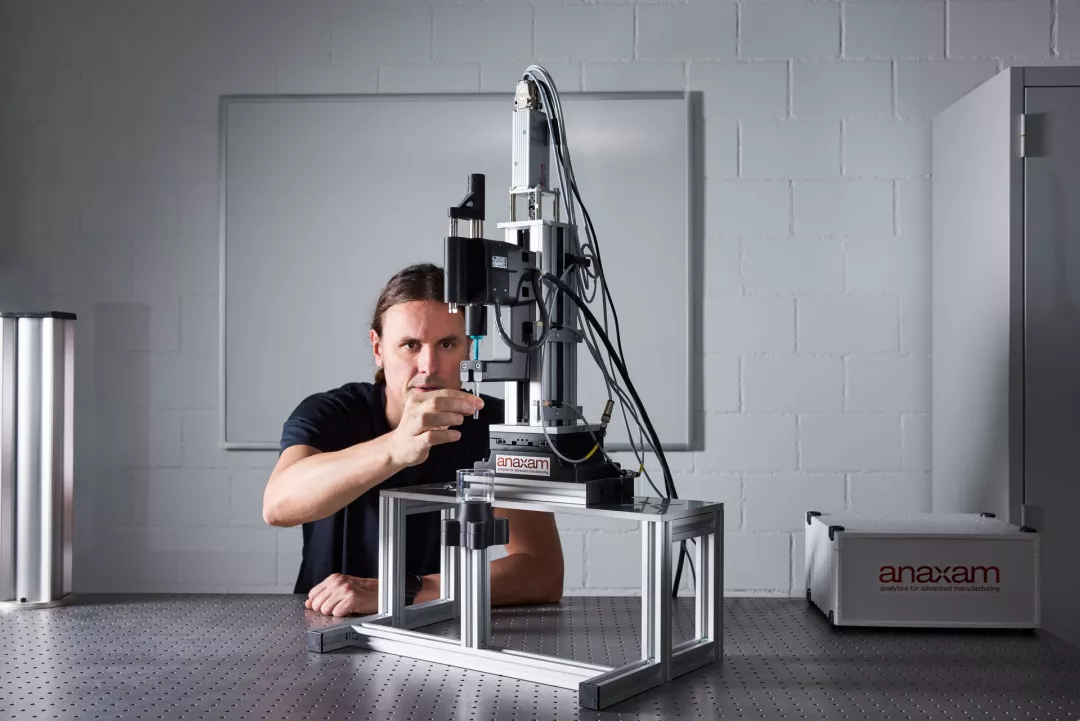

• 3D-printed aluminium heat sink for cooling the injection motor

• Magnetic linear spring to prevent unintentional lowering of the injection motor rotor

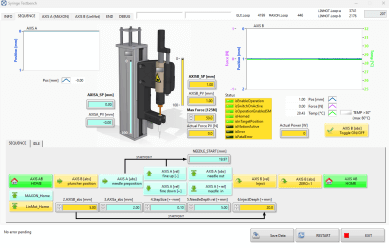

• Development of the control software

• Setting up and commissioning the hardware and software

• Testing different injection speeds

• Calibrating the force-displacement measurement

• Injection tests in tissue samples

• Setting up the injection setup on the beamline

• Carrying out the customer-specific experiments