Diffraction

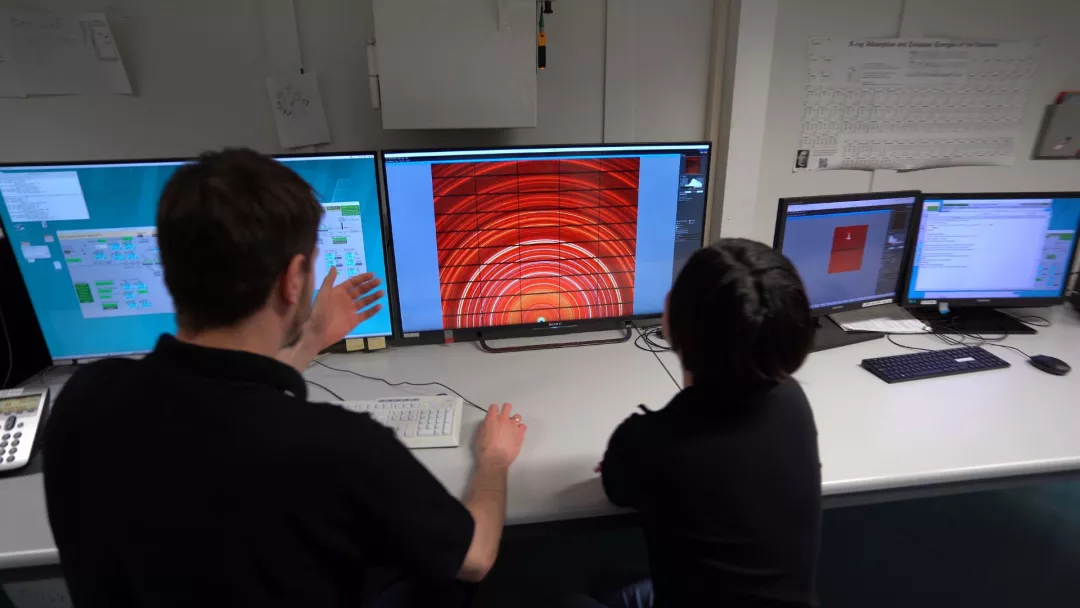

Neutron and Synchrotron Diffraction – Two Complementary Methods Providing Structural Information

The materials used in industrial products often undergo complex processes before reaching their final form and shape. Each of these processes influences the final structure and, consequently, the properties of the product. Diffraction is the available method for identifying phases and their morphology. It can be used for structural characterization as well as for texture and residual stress analysis.

Added Value and Benefits

- Enables precise determination of the crystal structure of materials.

- Identification and quantification of various material phases and their volume fractions.

- Measurement of internal stresses in materials, contributing to improved quality.

- High resolution and sample throughput for efficient analysis times.

- Real-time measurements possible – beneficial for process control and research.

Questions and Answers (FAQ)

- What is the difference between synchrotron and neutron diffraction?

Synchrotron diffraction provides high transmission for light elements and strong contrast for heavier elements. Neutron diffraction, on the other hand, offers strong contrast for light elements and higher transmission for heavier ones. This means that the two methods provide different but complementary contrast capabilities. More information

- In which industries is diffraction analysis commonly used?

Commonly applied in the coatings industry, mining, semiconductors, and pharmaceutical research.

- Can diffraction be used for quality control?

Yes, it can be used to identify manufacturing defects and improve products and processes.

- How accurate is diffraction analysis?

It enables highly precise measurements, even detecting variations at the atomic level.

- What sample preparation is required for diffraction analysis?

Samples must be specifically prepared and often cut to a defined size.

Contact

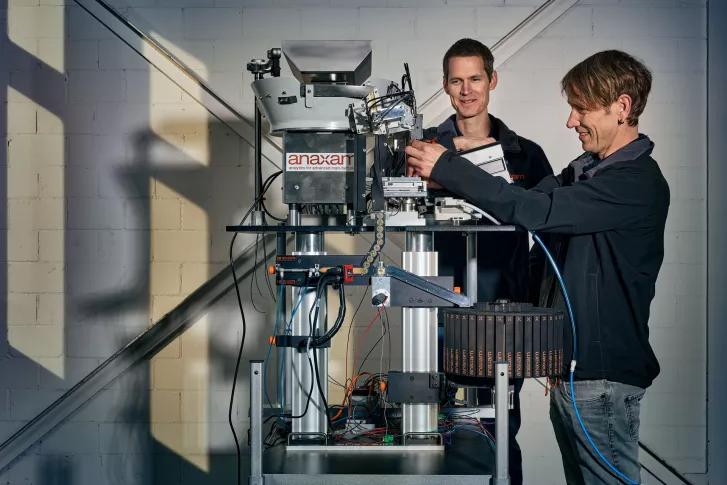

Interested in gaining deeper insights into your materials? Contact ANAXAM for a no-obligation consultation. Learn how our diffraction analytics can help you reach your research and development goals.

Further key terms

Diffraction, phase characterization, structural analysis, residual stress analysis, materials science, crystallography