Investigation of a Renewable Metal Energy Carrier using high-resolution Synchrotron CT and Diffraction

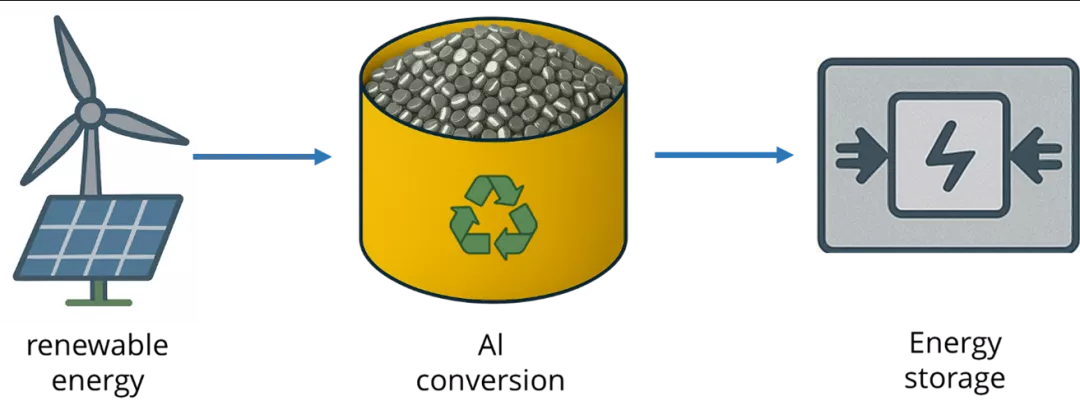

Apricot 366 GmbH is a startup focused on long-term storage and long-haul transport of renewable energy. Seasonal energy storage and transport of energy over long distances are key challenges for the integration of large amounts of fluctuating renewable energy harvesting throughout the year. Renewable Metal Energy Carriers (ReMEC) are highly suitable materials for large-scale seasonal energy storage. Among them, aluminum (Al) is particularly promising due to its high abundance, low cost, and high volumetric energy density. In places or at times of high abundance of renewable electricity, this electricity is used to convert aluminium oxide into elementary Al. When the energy demand is high and renewables are short in winter season, Al is oxidized by water to produce aluminium hydroxide in an exothermic reaction that produces hydrogen and heat; the hydrogen is subsequently used to produce electricity in a fuel cell (2), and the aluminium hydroxide is recirculated to produce new aluminium.

In order to effectively use Al as ReMEC, a fast Al-water reaction is required. A classic approach for increasing reactivity is to use Al in powder from. However, this comprises the risk of explosion when mixed with air. In our approach, Al microstructure engineering can be exploited to accelerate the Al-water reaction of granules. An energy carrier that is based on Al granules that react an order of magnitude faster than ordinary granules will make the operation of the Alu-to-Energy units of apricot 366 safer and more efficient.

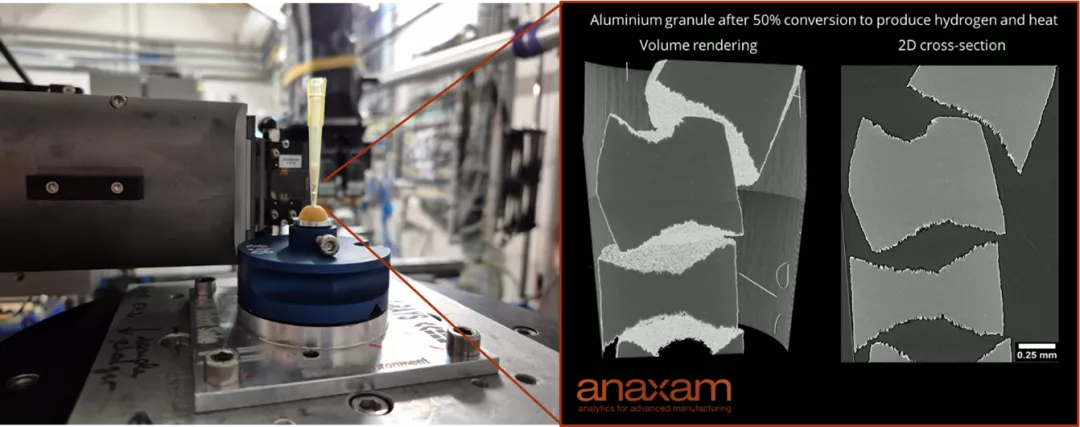

ANAXAM's applied material analytics using high-resolution synchrotron-CT and diffraction was successfully used to gain insight into the microstructural evolution of the aluminium granules during conversion to hydrogen and heat. The aim is to optimize Al microstructure for its specific use as an energy carrier.

The analytical services of ANAXAM are part of the Innosuisse Innovation Cheque project «A-FuME Aluminium Fuel Microstructure Engineering», an interdisciplinary collaboration with the Ostschweizer Fachhochschule - Institute for Environment and Process Engineering and the company apricot 366 GmbH.

ANAXAM provided us with amazing possibility to visualize the process of aluminium-water reaction of granular material and with the expertise to interpret the obtained images. Thus, we were able to proof that our idea to fine-tune reaction kinetics of our product for our specific application works indeed and gives us a great advantage over other approaches. We now know for sure that we are on the right track with our development, which gives us very high confidence into the path we have chosen.”

Dr. Michel Haller, CEO,

apricot 366 GmBH