Tailor-made Infrastructure

Tailor-made infrastructure – reproducing customer reality for the analytical services

Your benefits with tailor-made infrastructure

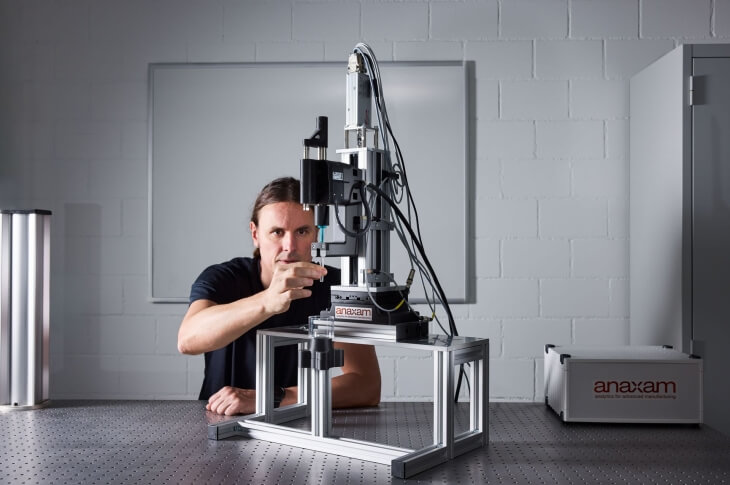

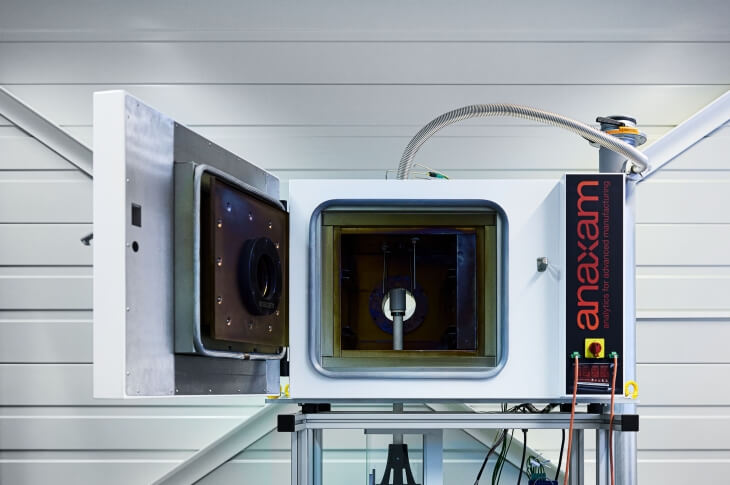

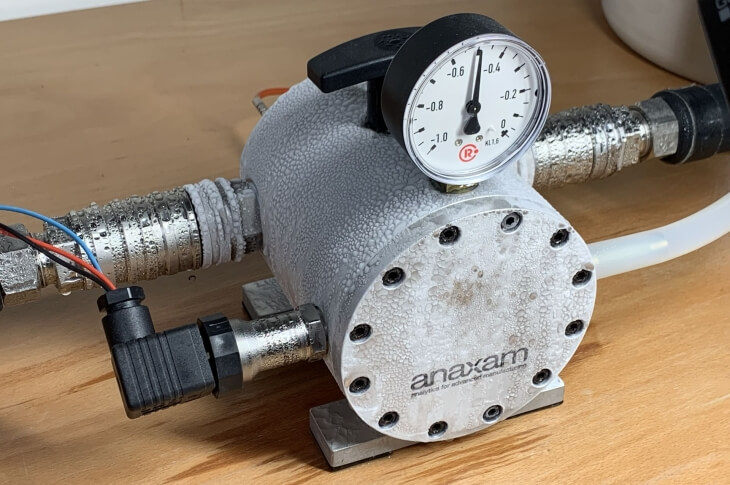

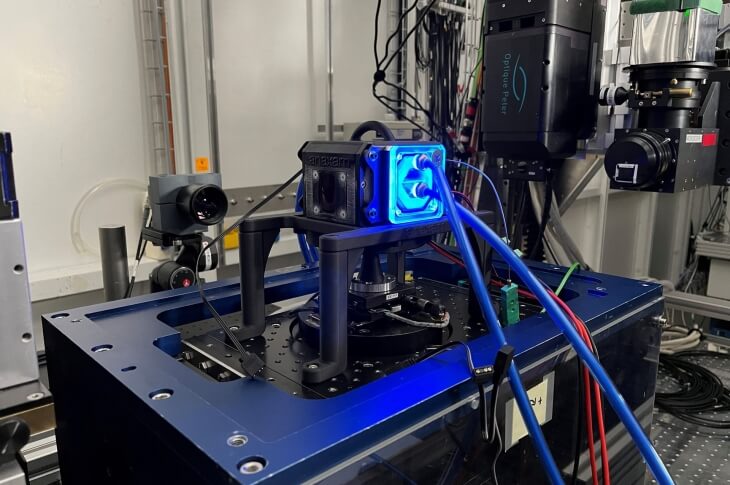

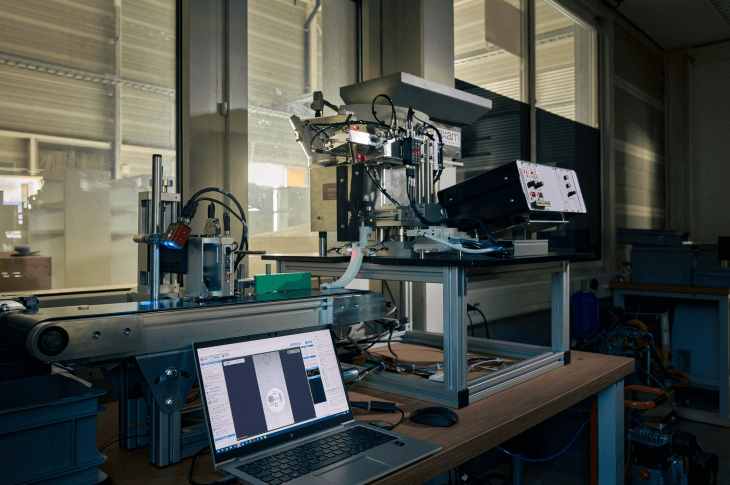

Dedicated equipment is essential to guarantee the best possible experimental conditions when performing customized experiments. Tailor-made infrastructure could include, for example, devices that allow the investigation of samples in-situ and in-operando under various environmental conditions.

In addition to the ability to vary measurement conditions, infrastructure in the form of automated sample manipulators is important in order to provide a higher sample throughput, leading to more efficient use of available beam time, and standardization of results. An overview of the possibilities for tailor-made infrastructure can be found below.

We are looking forward to supporting your analytical inquiries with our tailor-made infrastructure.

Possibilities for your tailor-made infrastructure

Creation process of the infrastructure

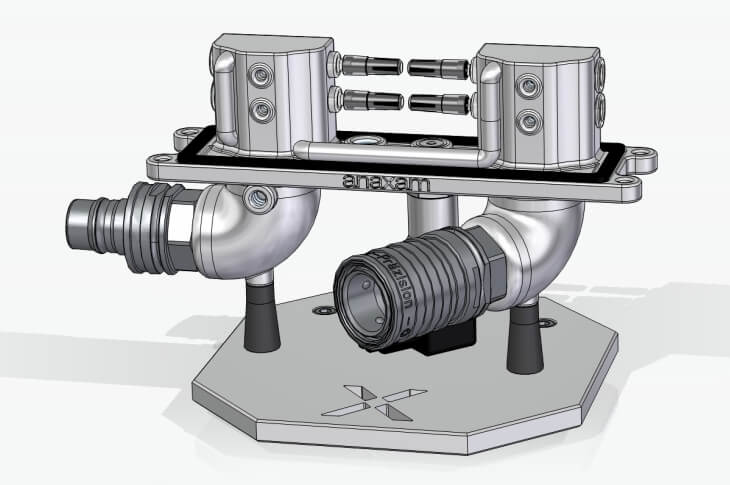

Our engineering and technical know-how enables us to create a tailor-made infrastructure to implement the customer reality for our analytical services. The entire infrastructure is fully integrated into the analytical measurement facilities for performing imaging, diffraction & scattering and spectroscopy experiments.

Conception

- Needs analysis of the customer

- Feasibility evaluation

- Concept development

- Finalization with customer

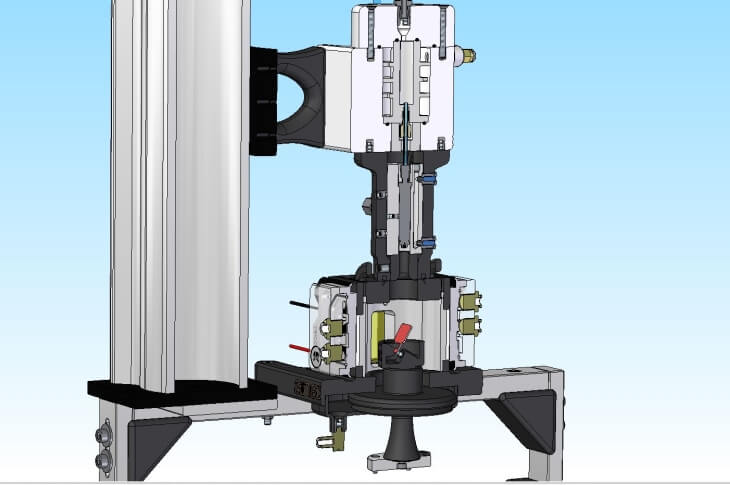

Design

- Creation of CAD models

- Creation of production drawings

- Creation of electronic diagrams

- Software planning

Implementation

- Manufacturing of the single part

- Assembly

- Programming of the control software

- Commissioning in the laboratory

In operation

- Transfer an die Beamlines

- Hardwareintegration in der Strahllinie

- Softwareintegration in der Strahllinie

- Durchführung der Experimente

Selection of tailor-made infrastructure

Our engineering and technical know-how allows us to create tailor-made infrastructure to reproduce customers’ reality for our analytical services. All infrastructure is fully integrated into analytical facilities for the performance of imaging, diffraction & scattering and spectroscopy experiments. The pool of infrastructure is continuously growing. Our existing infrastructure is very flexible, and can be modified according to customer needs.